Wires

Wires and wiring cables are used to supply power for lighting and electric appliances and equipment in residences, offices, and similar environments.

Wires Types

450 – 750 VOLTS – Copper Conductor PVC insulated SSA 1320, IEC 60227 & BS 6004

HO 7V – U With Solid Conductor – TYPE 60227 IEC 01

SPECIFICATIONS

For internal wiring of equipment rated voltage up to 1000 V AC and up to 750 V DC to earth.

| Catalogue Number | Nominal Cross Section | Conductor | Insulation Thickness | Overall Diameter | Weight of Finished Cable Approx | Maximum DC Resistance at 20 °C | Standard Packing Length | |

|---|---|---|---|---|---|---|---|---|

| Number of wires in Conductor | Diameter of Conductor Approx | |||||||

| mm2 | mm | mm | mm | Kg/Km | Ohm/Km | M±5% | ||

| 0C010004xx | 1×1.5 | 1 | 1.38 | 0.7 | 3.2 | 21 | 12.1 | 100 C |

| 0C010005xx | 1×2.5 | 1 | 1.78 | 0.8 | 3.9 | 34 | 7.41 | 100 C |

| 0C010006xx | 1×4 | 1 | 2.25 | 0.8 | 4.4 | 50 | 4.61 | 100 C |

| 0C010007xx | 1×6 | 1 | 2.76 | 0.8 | 5.0 | 70 | 3.08 | 100 C |

| 0C010008xx | 1×10 | 1 | 3.57 | 1.0 | 6.4 | 115 | 1.83 | 100 C |

| Color | Green/Yellow | Blue | Black | Green | Red | Yellow | Brown | Grey | Orange | White |

|---|---|---|---|---|---|---|---|---|---|---|

| Code | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 |

For required colour replace the last two digits – xx, by color code.

450 – 750 VOLTS – Copper Conductor PVC insulated SSA 1320, IEC 60227 & BS 6004

HO 7V – R With Stranded Conductor – TYPE 60227 IEC 01

SPECIFICATIONS

For internal wiring of equipment rated voltage up to 1000 V AC and up to 750 V DC to earth.

| Catalogue Number | Nominal Cross Section | Conductor | Insulation Thickness | Overall Diameter | Weight of Finished Cable Approx | Maximum DC Resistance at 20 °C | Standard Packing Length | |

|---|---|---|---|---|---|---|---|---|

| Number of Wires in Conductor | Diameter of Conductor Approx | |||||||

| mm2 | mm | mm | mm | Kg/Km | Ohm/Km | M±5% | ||

| 0C010104xx | 1×1.5 | 7 | 1.50 | 0.7 | 3.3 | 22 | 12.1 | 100 C |

| 0C010105xx | 1×2.5 | 7 | 2.01 | 0.8 | 4.0 | 35 | 7.41 | 100 C |

| 0C010106xx | 1×4 | 7 | 2.55 | 0.8 | 4.6 | 52 | 4.61 | 100 C |

| 0C010107xx | 1×6 | 7 | 3.12 | 0.8 | 5.2 | 71 | 3.08 | 100 C |

| 0C010108xx | 1×10 | 7 | 4.05 | 1.0 | 6.7 | 116 | 1.83 | 100 C |

| 0C010109xx | 1×16 | 7 | 5.10 | 1.0 | 7.8 | 185 | 1.15 | 100 C |

| 0C010110xx | 1×25 | 7 | 6.42 | 1.2 | 9.7 | 290 | 0.727 | 100 C |

| 0C010111xx | 1×35 | 7 | 7.65 | 1.2 | 10.9 | 390 | 0.524 | 100 C |

| 000101xx12 | 1×50 | 19 | 8.90 | 1.4 | 12.8 | 525 | 0.387 | 3000 D |

| 000101xx13 | 1×70 | 19 | 10.70 | 1.4 | 14.6 | 735 | 0.268 | 3000 D |

| 000101xx14 | 1×95 | 19 | 12.60 | 1.6 | 17.1 | 1010 | 0.193 | 3000 D |

| 000101xx15 | 1×120 | 37 | 14.21 | 1.6 | 18.8 | 1260 | 0.153 | 2000 D |

| 000101xx16 | 1×150 | 37 | 15.75 | 1.8 | 20.9 | 1540 | 0.124 | 2000 D |

| 000101xx17 | 1×185 | 37 | 17.64 | 2.0 | 23.3 | 1940 | 0.0991 | 2000 D |

| 000101xx18 | 1×240 | 61 | 20.25 | 2.2 | 26.6 | 2550 | 0.0754 | 1000 D |

| 000101xx19 | 1×300 | 61 | 22.68 | 2.4 | 29.6 | 3180 | 0.0601 | 1000 D |

| 000101xx20 | 1×400 | 61 | 25.65 | 2.6 | 33.2 | 4050 | 0.0470 | 500 D |

| 000101xx21 | 1×500 | 61 | 28.8 | 2.8 | 37.0 | 5050 | 0.0366 | 500 D |

| 000101xx22 | 1×630 | 127/91 | 32.76 | 2.8 | 41.0 | 6050 | 0.0283 | 500 D |

| Color | Green/Yellow | Blue | Black | Green | Red | Yellow | Brown | Grey | Orange | White |

|---|---|---|---|---|---|---|---|---|---|---|

| Code | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 |

For required colour replace the last two digits – xx, by color code.

450 – 750 VOLTS – Copper Conductor PVC insulated SSA 1320, IEC 60227 & BS 6004

HO 7V – K With Flexible Conductor – TYPE 60227 IEC 02

SPECIFICATIONS

For internal wiring of equipment rated voltage up to 1000 V AC and up to 750 V DC to earth.

| Catalogue Number | Nominal Cross Section | Conductor | Insulation Thickness | Overall Diameter | Weight of Finished Cable Approx. | Maximum DC Resistance at 20 ° C | Standard Packing Length | |

|---|---|---|---|---|---|---|---|---|

| Approx. No & Nom. strand Diameter | Diameter of Conductor Approx. | |||||||

| mm2 | No x mm | mm | mm | mm | Kg/Km | Ohm/Km | M±5% | |

| 0C010504xx | 1.x1.5 | 28×0.25 | 1.7 | 0.7 | 3.4 | 23 | 13.3 | 100 C |

| 0C010505xx | 1×2.5 | 46×0.25 | 2.2 | 0.8 | 4.1 | 35 | 7.98 | 100 C |

| 0C010506xx | 1×4 | 51×0.30 | 3.1 | 0.8 | 4.8 | 51 | 4.95 | 100 C |

| 0C010507xx | 1×6 | 77×0.30 | 3.8 | 0.8 | 5.3 | 71 | 3.30 | 100 C |

| 0C010508xx | 1×10 | 74×0.40 | 5.0 | 1.0 | 6.8 | 125 | 1.91 | 100 C |

| 0C010509xx | 1×16 | 118×0.40 | 6.3 | 1.0 | 8.1 | 195 | 1.21 | 100 C |

| 0C010510xx | 1×25 | 183×0.40 | 6.4 | 1.2 | 9.2 | 300 | 0.780 | 100 C |

| 0C010511xx | 1×35 | 257×0.40 | 9.2 | 1.2 | 10.5 | 410 | 0.554 | 100 C |

| 000105xx12 | 1×50 | 371×0.40 | 11.0 | 1.4 | 13.9 | 585 | 0.386 | 1000 D |

| 000105xx13 | 1×70 | 337×0.50 | 13.0 | 1.4 | 16.0 | 810 | 0.272 | 1000 D |

| 000105xx14 | 1×95 | 444×0.50 | 15.2 | 1.6 | 18.2 | 1065 | 0.206 | 1000 D |

| 000105xx15 | 1×120 | 570×0.50 | 17.0 | 1.6 | 20.2 | 1335 | 0.161 | 1000 D |

| 000105xx16 | 1×150 | 712×0.50 | 19.0 | 1.8 | 22.5 | 1600 | 0.129 | 1000 D |

| 000105xx17 | 1×185 | 864×0.50 | 21.0 | 2.0 | 24.9 | 2000 | 0.106 | 1000 D |

| 000105xx18 | 1×240 | 1140×0.50 | 24.0 | 2.2 | 28.4 | 2500 | 0.0801 | 1000 D |

| Color | Green/Yellow | Blue | Black | Green | Red | Yellow | Brown | Grey | Orange | White |

|---|---|---|---|---|---|---|---|---|---|---|

| Code | 01 | 02 | 03 | 04 | 05 | 06 | 07 | 08 | 09 | 10 |

For required colour replace the last two digits – xx, by color code.

| No. & Cross sectional area of conductor | No. of wires in conductor | Radial Thickness of insulation | Radial Thickness of sheath | Mean overall dia. or dimensions | Maximum DC Resistance at 20 °C | Approx. Weight | |

|---|---|---|---|---|---|---|---|

| Lower Limit | Upper Limit | ||||||

| mm² | mm | mm | mm | mm | mm | Ω/Km | Kg/Km |

| 1×1.0 | 1 | 0.6 | 0.8 | 3.8 | 4.5 | 18.1 | 28 |

| 1×1.5 | 1 | 0.7 | 0.8 | 4.2 | 4.9 | 12.1 | 36 |

| 1×2.5 | 1 | 0.8 | 0.8 | 4.8 | 5.8 | 7.41 | 51 |

| 1×4 | 7 | 0.8 | 0.9 | 5.4 | 6.8 | 4.61 | 74 |

| 1×6 | 7 | 0.8 | 0.9 | 6.0 | 7.4 | 3.08 | 96 |

| 1×10 | 7 | 1.0 | 0.9 | 7.2 | 8.8 | 1.83 | 150 |

| 1×16 | 7 | 1.0 | 1.0 | 8.4 | 10.5 | 1.15 | 220 |

| 1×25 | 7 | 1.2 | 1.1 | 10.0 | 12.5 | 0.727 | 335 |

| 1×35 | 7 | 1.2 | 1.1 | 11.0 | 13.5 | 0.524 | 440 |

| 2×1.0 | 1 | 0.6 | 0.9 | 4.0×6.2 | 4.7×7.4 | 18.1 | 53 |

| 2×1.5 | 1 | 0.7 | 0.9 | 4.4×7.0 | 5.4×8.4 | 12.1 | 71 |

| 2×2.5 | 1 | 0.8 | 1.0 | 5.2×8.4 | 6.2×9.8 | 7.41 | 106 |

| 2×4 | 7 | 0.8 | 1.0 | 5.6×9.6 | 7.2×11.5 | 4.61 | 150 |

| 2×6 | 7 | 0.8 | 1.1 | 6.4×10.5 | 8.0×13.0 | 3.08 | 200 |

| 2×10 | 7 | 1.0 | 1.2 | 7.8×13.0 | 9.6×16.0 | 1.83 | 320 |

| 2×16 | 7 | 1.0 | 1.3 | 9.0×15.5 | 11.0×18.5 | 1.15 | 460 |

| 3×1.0 | 1 | 0.6 | 0.9 | 4.0×8.4 | 4.7×9.8 | 18.1 | 76 |

| 3×1.5 | 1 | 0.7 | 0.9 | 4.4×9.8 | 5.4×11.5 | 12.1 | 106 |

| 3×2.5 | 1 | 0.8 | 1.0 | 5.2×11.5 | 6.2×13.5 | 7.41 | 160 |

| 3×4 | 7 | 0.8 | 1.1 | 5.8×13.5 | 7.4×16.5 | 4.61 | 230 |

| 3×6 | 7 | 0.8 | 1.1 | 6.4×15.0 | 8.0×18.0 | 3.08 | 300 |

| 3×10 | 7 | 1.0 | 1.2 | 7.8×19.0 | 9.6×22.5 | 1.83 | 475 |

| 3×16 | 7 | 1.0 | 1.3 | 9.0×22.0 | 11.0×26.5 | 1.15 | 690 |

Construction :

Plain annealed copper conductor Class 1 & 2 as per BS 6360.

- PVC insulation.

- PVC sheath.

- The sheath shall be closely fitting but shall not adhere to the cores and in the case of twin and three-core, the cores shall be laid parallel.

Core Identification :

- Single : Brown or Blue

- Twin : Brown, Blue

- Three-core : Brown, Black (Centre core), Gray

- Single : Red or Black

- Twin : Red, Black

- Three-core : Red, Yellow (Centre core), Blue

Colour of Sheath :

- Single : Gray, (other colour on request)

- Flat Twin and three core : Gray

PVC Insulated, PVC Sheathed Cables with Earth Continuity Conductor, Flat Twin and Three Cores

Copper Conductor – Standard : BS 6004 300 / 500 VOLTS

| No. & Cross sectional area of conductor | No. of wires in conductor | Radial Thickness of insulation | Radial Thickness of sheath | Mean overall dia. or dimensions | Earth continuity cond. cross section | Maximum DC Resistance at 20 °C | Approx. Weight | |

|---|---|---|---|---|---|---|---|---|

| Lower Limit | Upper Limit | |||||||

| mm² | mm | mm | mm | mm | mm | mm² | Ω/Km | Kg/Km |

| 2×1.0 | 1 | 0.6 | 0.9 | 4.0×7.2 | 4.7×8.6 | 1.0 | 18.1 | 68 |

| 2×1.5 | 1 | 0.7 | 0.9 | 4.4×8.2 | 5.4×9.6 | 1.0 | 12.1 | 87 |

| 2×2.5 | 1 | 0.8 | 1.0 | 5.2×9.8 | 6.2×11.5 | 1.5 | 7.41 | 135 |

| 2×4 | 7 | 0.8 | 1.0 | 5.6×10.5 | 7.2×13.0 | 1.5 | 4.61 | 170 |

| 2×6 | 7 | 0.8 | 1.1 | 6.4×12.5 | 8.0×15.0 | 2.5 | 3.08 | 240 |

| 2×10 | 7 | 1.0 | 1.2 | 7.8×15.5 | 9.6×19.0 | 4. | 1.83 | 380 |

| 2×16 | 7 | 1.0 | 1.3 | 9.0×18.0 | 11.0×22.5 | 6 | 1.15 | 550 |

| 3×1.0 | 1 | 0.6 | 0.9 | 4.0×9.6 | 4.7×11.0 | 1.0 | 18.1 | 90 |

| 3×1.5 | 1 | 0.7 | 1.1 | 4.4×10.5 | 5.4×12.5 | 1.0 | 12.1 | 120 |

| 3×2.5 | 1 | 0.8 | 0.9 | 5.2×12.5 | 6.2×14.5 | 1.0 | 7.41 | 180 |

| 3×4 | 7 | 0.8 | 1.0 | 5.8×14.5 | 7.4×18.0 | 1.5 | 4.61 | 250 |

| 3×6 | 7 | 0.8 | 1.1 | 6.4×16.5 | 8.0×20.0 | 2.5 | 3.08 | 330 |

| 3×10 | 7 | 1.0 | 1.2 | 7.8×21.0 | 9.6×25.5 | 4. | 1.83 | 540 |

| 3×16 | 7 | 1.0 | 1.3 | 9.0×24.5 | 11.0×29.5 | 6 | 1.15 | 770 |

Construction :

Plain annealed copper conductor Class 1 & 2 as per BS 6360.

- PVC insulation.

- PVC sheath.

- The sheath shall be closely fitting but shall not adhere to the cores, which shall be laid parallel with uninsulated earth continuity conductor.

Colour for Core Identification :

- Twin : Brown, Blue

- Three-core : Brown, Black (Centre core), Gray

- Twin : Red, Black

- Three-core : Red, Yellow (Centre core), Blue

Position of continuity conductor :

- Twin : Centrally placed between cores in same plane.

- Three cores : Centrally placed between black and gray cores in same plane (OR) place between yellow and blue.

Colour of Outer sheath :

- Gray

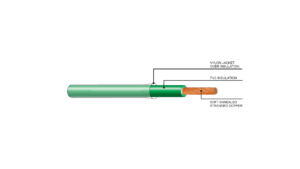

THHN/THWN BUILDING WIRE 90 DEG. C 600 VOLTS

Table 1

Current carrying capacities of THWN and THHN insulated Copper Conductors rated 600 V not more than three conductors in raceway or cable or earth (Direct Buried) based on ambient temp. of 30 deg. C

| Size | THWN | THHN |

|---|---|---|

| AWG | AMPS | AMPS |

| 18 | 14 | |

| 16 | 18 | |

| 14 | 20 | 25 |

| 12 | 25 | 30 |

| 10 | 35 | 40 |

| 8 | 50 | 55 |

| 6 | 65 | 75 |

| 4 | 85 | 95 |

| 2 | 115 | 130 |

| 1/0 | 150 | 170 |

| 2/0 | 175 | 195 |

Table 2

Current carrying capacities of THWN and THHN single insulated Copper Conductors rated 600 V in free air based on ambient air temp. of 30 deg. C

| Size | THWN | THHN |

|---|---|---|

| AWG | AMPS | AMPS |

| 18 | 18 | |

| 16 | 24 | |

| 14 | 30 | 35 |

| 12 | 35 | 40 |

| 10 | 50 | 55 |

| 8 | 70 | 80 |

| 6 | 95 | 105 |

| 4 | 125 | 140 |

| 2 | 170 | 190 |

| 1/0 | 230 | 260 |

| 2/0 | 265 | 300 |

Table 3 – CORRECTION FACTORS

| Ambient Temp °C | THWN (75 °C) | THHN (90 °C) |

|---|---|---|

| 21 – 25 | 1.05 | 1.04 |

| 26 – 30 | 1.00 | 1.00 |

| 31 – 35 | 0.94 | 0.96 |

| 36 – 40 | 0.88 | 0.91 |

| 41 – 45 | 0.82 | 0.87 |

| 46 – 50 | 0.75 | 0.82 |

| 51 – 55 | 0.67 | 0.76 |

| 56 – 60 | 0.58 | 0.71 |

| 61 – 70 | 0.33 | 0.58 |

| 71 – 80 | – | 0.41 |

For ambient temp. other than 30 deg. C. multiply the ampacities given in tables 1 & 2 by the appropriate factor given in Table 3.

Table 4 : Conduit Fill

Maximum Number of THHN/THWN Conductors in conduit or tubing as per 1990 NEC

| Size AWG | Conduit trade size (inches) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 3-1/2 | 4 | 5 | 6 | |

| 18* | 19 | 34 | 55 | 97 | 132 | 216 | – | – | – | – | – | – |

| 16* | 15 | 26 | 43 | 76 | 104 | 169 | – | – | – | – | – | – |

| 14 | 13 | 24 | 39 | 69 | 94 | 154 | – | – | – | – | – | – |

| 12 | 10 | 18 | 29 | 51 | 70 | 114 | 164 | – | – | – | – | – |

| 10 | 6 | 11 | 18 | 32 | 44 | 73 | 104 | 160 | – | – | – | – |

| 8 | 3 | 5 | 9 | 16 | 22 | 36 | 51 | 79 | 106 | 136 | – | – |

| 6 | 1 | 4 | 6 | 11 | 15 | 26 | 37 | 57 | 76 | 98 | 154 | – |

| 4 | 1 | 2 | 4 | 7 | 9 | 16 | 22 | 35 | 47 | 60 | 94 | 137 |

| 3 | 1 | 1 | 3 | 6 | 8 | 13 | 19 | 29 | 39 | 51 | 80 | 116 |

| 2 | 1 | 1 | 3 | 5 | 7 | 11 | 16 | 25 | 33 | 43 | 67 | 97 |

| 1 | – | 1 | 1 | 3 | 5 | 8 | 12 | 18 | 25 | 32 | 50 | 72 |

| 1/0 | – | 1 | 1 | 3 | 4 | 7 | 10 | 15 | 21 | 27 | 42 | 61 |

| 2/0 | – | 1 | 1 | 2 | 3 | 6 | 8 | 13 | 17 | 22 | 35 | 51 |

* Listed as TFFN

Table 5 : Combination of conductors

For groups of combinations of conductors, the conduit or tubing shall be of such size that the sum of the cross sectional areas of the individual conductors will not be more than percentage of the internal cross sectional are of the conduit or tubing as shown below :

| No of Conductors | 1 | 2 | 3 | 4 | over 4 |

|---|---|---|---|---|---|

| Percentage | 53 | 31 | 40 | 40 | 40 |

300 – 500 VOLTS – Copper Conductor PVC Insulated and Sheathed

SSA 1450, IEC 60227 ( IEC 10)

| Catalogue Number | Nominal Cross Section | Number of Wires in Conductor | Diameter of Conductor Approx | Insulation Thickness | Sheath Thickness | Overall Diameter | Weight of Finished Cable Approx | Maximum DC Resistance at 20°C | Packing |

|---|---|---|---|---|---|---|---|---|---|

| mm² | mm | mm | mm | mm | Kg/Km | Ohm/Km | M±5% | ||

| 0B01002408 | 2×1.5 | 1 | 1.38 | 0.7 | 1.2 | 10.0 | 120 | 12.1 | 100 C |

| 0B01002508 | 2×2.5 | 1 | 1.78 | 0.8 | 1.2 | 11.5 | 165 | 7.41 | 100 C |

| 0B01002608 | 2×4 | 1 | 2.25 | 0.8 | 1.2 | 12.5 | 215 | 4.61 | 100 C |

| 0B01002708 | 2×6 | 1 | 2.76 | 0.8 | 1.2 | 13.5 | 270 | 3.08 | 100 C |

| 0B01002808 | 2×10 | 1 | 3.57 | 1.0 | 1.4 | 16.5 | 440 | 1.83 | 1000/2000 |

| 0B01003408 | 3×1.5 | 1 | 1.38 | 0.7 | 1.2 | 10.5 | 140 | 12.1 | 100 C |

| 0B01003508 | 3×2.5 | 1 | 1.78 | 0.8 | 1.2 | 12.0 | 195 | 7.41 | 100 C |

| 0B01003608 | 3×4 | 1 | 2.25 | 0.8 | 1.2 | 13.0 | 250 | 4.61 | 100 C |

| 0B01003708 | 3×6 | 1 | 2.76 | 0.8 | 1.4 | 14.5 | 345 | 3.08 | 100 C |

| 0B01003808 | 3×10 | 1 | 3.57 | 1.0 | 1.4 | 17.5 | 540 | 1.83 | 1000/2000 |

| 0B01004408 | 4×1.5 | 1 | 1.38 | 0.7 | 1.2 | 11.5 | 165 | 12.1 | 100 C |

| 0B01004508 | 4×2.5 | 1 | 1.78 | 0.8 | 1.2 | 13.0 | 235 | 7.41 | 100 C |

| 0B01004608 | 4×4 | 1 | 2.25 | 0.8 | 1.4 | 14.5 | 325 | 4.61 | 100 C |

| 0B01004708 | 4×6 | 1 | 2.76 | 0.8 | 1.4 | 16.0 | 430 | 3.08 | 1000/2000 |

| 0B01004808 | 4×10 | 1 | 3.57 | 1.0 | 1.4 | 19.0 | 665 | 1.83 | 1000/2000 |

| 0B01005408 | 5×1.5 | 1 | 1.38 | 0.7 | 1.2 | 12.0 | 195 | 12.1 | 100 C |

| 0B01005508 | 5×2.5 | 1 | 1.78 | 0.8 | 1.2 | 14.0 | 285 | 7.41 | 100 C |

| 0B01005608 | 5×4 | 1 | 2.25 | 0.8 | 1.4 | 16.0 | 405 | 4.61 | 100 C |

| 0B01005708 | 5×6 | 1 | 2.78 | 0.8 | 1.4 | 17.5 | 530 | 3.08 | 1000/2000 |

| 0B01005808 | 5×10 | 1 | 3.57 | 1.0 | 1.4 | 21.0 | 810 | 1.83 | 1000/2000 |

| Color Code | |

|---|---|

| 2 cores : Red, Black | 2 cores : Light Blue, Brown |

| 3 cores : Red, Yellow and Blue | 3 cores : Light Blue, Black, Brown |

| 4 cores : Red, Yellow, Blue and Black | 4 cores : Light Blue, Black, Brown, Black |

| 5 cores : Red, Yellow, Blue, Black and Green | 5 cores : Light Blue, Black, Brown, Brown, Black |

For Green/Yellow Core – Replace 5th digits by 3.

For Green/Yellow Core – add letter “J” at the end of item code.

Outer Sheath – Gray

| Catalogue Number | Nominal Cross Section | Number of Wires in Conductor | Diameter of Conductor Approx | Insulation Thickness | Sheath Thickness | Overall Diameter | Weight of Finished Cable Approx | Maximum DC Resistance at 20°C | Packing |

|---|---|---|---|---|---|---|---|---|---|

| mm² | mm | mm | mm | mm | Kg/Km | Ohm/Km | M±5% | ||

| 0B01012408 | 2×1.5 | 7 | 1.50 | 0.7 | 1.2 | 10.5 | 125 | 12.1 | 100 C |

| 0B01012508 | 2×2.25 | 7 | 2.01 | 0.8 | 1.2 | 12.0 | 170 | 7.41 | 100 C |

| 0B01012608 | 2×4 | 7 | 2.55 | 0.8 | 1.2 | 13.0 | 220 | 4.61 | 100 C |

| 0B01012708 | 2×6 | 7 | 3.12 | 0.8 | 1.2 | 14.0 | 280 | 3.08 | 100 C |

| 0B01012808 | 2×10 | 7 | 4.05 | 1.0 | 1.4 | 17.5 | 470 | 1.83 | 1000/2000 |

| 0B01012908 | 2×16 | 7 | 5.10 | 1.0 | 1.4 | 20.0 | 650 | 1.15 | 1000/2000 |

| 0B01012108 | 2×25 | 7 | 6.42 | 1.2 | 1.4 | 24.0 | 980 | 0.727 | 1000 |

| 0B01012118 | 2×35 | 7 | 7.65 | 1.2 | 1.6 | 27.5 | 1300 | 0.524 | 1000 |

| 0B01013408 | 3×1.5 | 7 | 1.50 | 0.7 | 1.2 | 11.0 | 145 | 12.1 | 100 C |

| 0B01013508 | 3×2.5 | 7 | 2.01 | 0.8 | 1.2 | 12.5 | 200 | 7.41 | 100 C |

| 0B01013608 | 3×4 | 7 | 2.55 | 0.8 | 1.2 | 13.5 | 270 | 4.61 | 100 C |

| 0B01013708 | 3×6 | 7 | 3.12 | 0.8 | 1.4 | 15.5 | 360 | 3.08 | 100 C |

| 0B01013808 | 3×10 | 7 | 4.05 | 1.0 | 1.4 | 19.0 | 570 | 1.83 | 1000/2000 |

| 0B01013908 | 3×16 | 7 | 5.10 | 1.0 | 1.4 | 21.5 | 830 | 1.15 | 1000/2000 |

| 0B01013108 | 3×25 | 7 | 6.42 | 1.2 | 1.6 | 26.0 | 1255 | 0.727 | 1000 |

| 0B01013118 | 3×35 | 7 | 7.65 | 1.2 | 1.6 | 29.0 | 1640 | 0.524 | 1000 |

| 0B01014408 | 4×1.5 | 7 | 1.50 | 0.7 | 1.2 | 12.0 | 165 | 12.1 | 100 C |

| 0B01014508 | 4×2.5 | 7 | 2.01 | 0.8 | 1.2 | 13.5 | 240 | 7.41 | 100 C |

| 0B01014608 | 4×4 | 7 | 2.55 | 0.8 | 1.4 | 15.0 | 330 | 4.61 | 100 C |

| 0B01014708 | 4×6 | 7 | 3.12 | 0.8 | 1.4 | 17.0 | 460 | 3.08 | 1000/2000 |

| 0B01014808 | 4×10 | 7 | 4.05 | 1.0 | 1.4 | 20.5 | 700 | 1.83 | 1000/2000 |

| 0B01014908 | 4×16 | 7 | 5.10 | 1.0 | 1.4 | 23.5 | 1025 | 1.15 | 1000/2000 |

| 0B01014108 | 4×25 | 7 | 6.42 | 1.2 | 1.6 | 28.5 | 1590 | 0.727 | 1000 |

| 0B01014118 | 4×35 | 7 | 7.65 | 1.2 | 1.6 | 32.0 | 2040 | 0.524 | 1000 |

| 0B01015408 | 5×1.5 | 7 | 1.50 | 0.7 | 1.2 | 12.0 | 200 | 12.1 | 100 C |

| 0B01015508 | 5×2.5 | 7 | 2.01 | 0.8 | 1.2 | 14.5 | 290 | 7.41 | 100 C |

| 0B01015608 | 5×4 | 7 | 2.55 | 0.8 | 1.4 | 17.0 | 410 | 4.61 | 100 C |

| 0B01015708 | 5×6 | 7 | 3.12 | 0.8 | 1.4 | 18.5 | 550 | 3.08 | 1000/2000 |

| 0B01015808 | 5×10 | 7 | 4.05 | 1.0 | 1.4 | 22.0 | 850 | 1.83 | 1000/2000 |

| 0B01015908 | 5×16 | 7 | 5.10 | 1.0 | 1.6 | 26.0 | 1250 | 1.15 | 1000/2000 |

| 0B01015108 | 5×25 | 7 | 6.42 | 1.2 | 1.6 | 31.5 | 1860 | 0.727 | 1000 |

| 0B01015118 | 5×35 | 7 | 7.65 | 1.2 | 1.6 | 35.0 | 2540 | 0.524 | 1000 |

| Color Code | |

|---|---|

| 2 cores : Red, Black | 2 cores : Light Blue, Brown |

| 3 cores : Red, Yellow and Blue | 3 cores : Light Blue, Black, Brown |

| 4 cores : Red, Yellow, Blue and Black | 4 cores : Light Blue, Black, Brown, Black |

| 5 cores : Red, Yellow, Blue, Black and Green | 5 cores : Light Blue, Black, Brown, Brown, Black |

For Green/Yellow Core – Replace 5th digits by 3.

For Green/Yellow Core – add letter “J” at the end of item code.

Outer Sheath – Gray

300 – 500 VOLTS – Flexible Copper Conductor PVC Insulated and Sheathed

HO 5 VV-F, BS 6500, IEC 60227 (IEC 53)

| Catalogue Number | Nominal Cross Section Approx. | Number & dia of wires in Conductor | Diameter of Conductor Approx | Weight of Insulation Thickness | Thickness of Sheath Approx. | Overall Diameter | Weight of Finished Cable Approx | Maximum DC Resistance at 20°C | Packing |

|---|---|---|---|---|---|---|---|---|---|

| mm² | no x mm | mm | mm | mm | mm | Kg/Km | Ohm/Km | M±5% | |

| 0B01052210 | 2×0.75 | 22×0.20 | 1.1 | 0.6 | 0.8 | 7.2 | 56 | 26.0 | 100 |

| 0B01052310 | 2×1 | 29×0.20 | 1.3 | 0.6 | 0.8 | 7.5 | 65 | 19.5 | 100 |

| 0B01052410 | 2×1.5 | 28×0.25 | 1.6 | 0.7 | 0.8 | 8.6 | 80 | 13.3 | 100 |

| 0B01052510 | 2×2.5 | 46×0.25 | 2.1 | 0.8 | 1.0 | 10.6 | 130 | 7.98 | 100 |

| 0B01053210 | 3×0.75 | 22×0.20 | 1.1 | 0.6 | 0.8 | 7.6 | 65 | 26.0 | 100 |

| 0B01053310 | 3×1 | 29×0.20 | 1.3 | 0.6 | 0.8 | 8.0 | 80 | 19.5 | 100 |

| 0B01053410 | 3×1.5 | 28×0.25 | 1.6 | 0.7 | 0.9 | 9.4 | 100 | 13.3 | 100 |

| 0B01053510 | 3×2.5 | 46×0.25 | 2.1 | 0.8 | 1.1 | 11.4 | 155 | 7.98 | 100 |

| 0B01054210 | 4×0.75 | 22×0.20 | 1.1 | 0.6 | 0.8 | 8.3 | 80 | 26.0 | 100 |

| 0B01054310 | 4×1 | 29×0.20 | 1.3 | 0.6 | 0.9 | 9.0 | 95 | 19.5 | 100 |

| 0B01054410 | 4×1.5 | 28×0.25 | 1.6 | 0.7 | 1.0 | 10.5 | 130 | 13.3 | 100 |

| 0B01054510 | 4×2.5 | 46×0.25 | 2.1 | 0.8 | 1.1 | 12.5 | 200 | 7.98 | 100 |

| 0B01055210 | 5×0.75 | 22×0.20 | 1.1 | 0.6 | 0.9 | 9.3 | 105 | 26.0 | 100 |

| 0B01055310 | 5×1 | 29×0.20 | 1.3 | 0.6 | 0.9 | 9.8 | 125 | 19.5 | 100 |

| 0B01055410 | 5×1.5 | 28×0.25 | 1.6 | 0.7 | 1.1 | 11.6 | 160 | 13.3 | 100 |

| 0B01055510 | 5×2.5 | 46×0.25 | 2.1 | 0.8 | 1.2 | 13.9 | 245 | 7.98 | 100 |

| Color Code | |

|---|---|

| 2 cores : Light Blue, Brown | |

| 3 cores : Light Blue, Black, Brown | 3 cores : Light Blue, Brown, Green / Yellow |

| 4 cores : Light Blue, Black, Brown, Black | 4 cores : Light Blue, Black, Brown and Green / Yellow |

| 5 cores : Light Blue, Black, Brown, Brown, Black | 5 cores : Light Blue, Black, Brown, Black and Green / Yellow |

For Green/Yellow Core – add letter “J” at the end of item code.

Outer Sheath – White

PVC Insulated, Non Sheathed Flexible Cords for Internal Wiring.Single Core and Twisted Twin

Copper Conductor – Standard(s): BS 6004 IEC 60227 (IEC 06)

300 – 500 Volts HO5V-K

Conductor | Radial Thickness of insulation | Mean Overall diameter (upper limit single) | Maximum DC Resistance at 20 °C | Approximate weight | ||

|---|---|---|---|---|---|---|

| Nominal Cross Section | Nominal diameter of wire | Single | Twin | |||

| mm² | mm | mm | mm | Ω/Km | Kg/Km | Kg/Km |

| 0.5 | 0.20 | 0.6 | 2.4 | 39.0 | 9 | 19 |

| 0.75 | 0.20 | 0.6 | 2.6 | 26.0 | 12 | 24 |

| 1.0 | 0.20 | 0.6 | 2.8 | 19.5 | 15 | 29 |

Note :

- The cord may be available in twisted form.

- For solid wire conductor equivalent cables, please refer to BS 6004 or IEC 60227.

- For larger size of flexible conductor cables, please refer to BS 6004 or IEC 60227.

Construction :

- Annealed Copper conductor as per BS 6360 or IEC 60228, CLASS 5.

- PVC Insulation

Core Identification :

- Green/Yellow, Blue or any other colour.

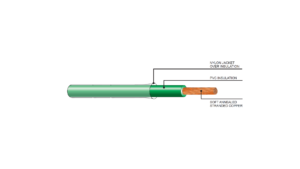

450 – 750 PVC Insulated Wires with solid (Class 1) Copper conductors (HO7V-U)

450 – 750 PVC Insulated Wires with stranded (Class 2) Copper conductors (HO7V-R)

450 – 750 PVC Insulated Wires with Flexible (Class 5) Copper conductors (HO7V-K)

300 – 500 PVC Insulated and PVC Sheathed Copper conductors HO5VV-U, HO5VV-R & HO5VV-F

300 – 500 PVC Insulated non-sheathed flexible cords for internal wiring HO5V-K (single core and twisted twin)

PVC Insulated, Non-Sheathed Flexible Cords for Internal Wiring – Parallel Twin

Copper Conductor Standard(s): IEC 60227 (IEC 42)

300 / 300 VOLTS

Conductor

Radial Thickness of Insulation Mean overall dimensions Maximum DC Resistance at 20 °C Approx Weight Nom. Cross Sectional Area Maximum diameter of Wire Lower Limit Upper Limit mm² mm mm mm mm Ω/Km Kg/Km 2×0.50 0.16 0.8 2.5×5.0 3.0×6.0 39.0 22 2×0.75 0.16 0.8 2.7×5.4 3.2×6.4 26.0 28 Construction :

- Annealed Copper conductor as per BS 6360 Class 6.

- The conductors shall be laid parallel and covered with PVC insulation

- The insulation shall be provided with a groove on each side between the conductors to facilitate seperation of the cores.

380 V PVC Insulated non-sheathed flexible cords for internal wiring NYFAF (single core, three core and four core).

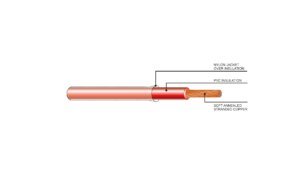

THHN/THWN BUILDING WIRE 90 DEG. C 600 VOLTS

CONSTRUCTION:

CONDUCTOR :

Soft drawn annealed copper conductor as per UL 83. Available in solid or stranded type for sizes 14, 12 and 10 AWG. Sizes 8 AWG and larger available in stranded only.

INSULATION :

Extruded polyvinyl Chloride (PVC) compound rated 75 °C and 90 °C.

JACKET :

Tough, smooth, heat and light stabilized, low moisture absorption nylon conforming to UL requirements for type THHN or THWN. This jacket offers a great degree of protection to the PVC insulation from abrasion and cut-through which may be encountered in pulling wire through conduits. Nylon has long been recognized as one of the toughest jacketing material used in wire and cable manufacturing.

FEATURES :

- Meets UL ‘VW-1 Flame Test requirements.

- Wet or dry locations – Rated 90 °C dry 75 °C wet.

- Resistant to gas and oil exposure : Rated gasoline and oil resistant II per UL.

- Versatile : Can be used as follows

a. THHN : 90 °C dry building wire

b. THWN : 75 °C wet and 90°C dry building wire

c. MTW : 90 °C machine tool wire - Pulls easier : tough smooth nylon jacket over PVC insulation.

- Small diameter : more conductors per conduit.

APPLICATIONS :

Type THHN – THWN building wires are intended for general purpose applications and may be installed in conduit, duct or other recognized raceways in wet or dry locations.

Type THHN – THWN wires are designed to operate at conductor temperatures of 75°C and 90°C for 600 volts service in wet and dry locations respectively. Applicable for both new work and rewiring installed where the smaller wire diameter permits additional circuits or larger conductors, to be installed in the conduit without exceeding maximum fill limitations.

Type THHN – THWN wires are also recommended for industrial installation where exceptional resistance to heat and corrosive atmospheres are needed, such as chemical plants, oil refineries, paper mills, etc.

THHN/THWN BUILDING WIRE 90 DEG. C 600 VOLTS

MARKINGS:

The wire is surface marked as follows:

Riyadh Electric Wire, Year of manufacture, Type THHN or THWN or TFFN Gasoline and Oil Resistant II, 600 Volts, VW – 1

Standards:

UL 83 – Underwriters Laboratories, Thermoplastic Insulated Wires and Cables.

UL 1063 – Underwriters Laboratories, Machine Tool Wires and Cables.

UL 1581 – Underwriters Laboratories, Reference standard for Electrical Wires, Cables and Flexible Cords.

600 Volts Copper Conductor PVC Insulated NYLON Jacketed THHN/THWN Wires UL 83, 1581

| AWG | Equiv. mm2 | Conductor | Insulation Thickness mm (Ave.) | Nylon Jacket Thickness mm (Min.) | Approx. Overall Diameter mm | Approx. Weight of Cond. Kg/Km | Standard DC Resistance at 20 °C Ohm/Km | Packing Length M (±5%) | |

|---|---|---|---|---|---|---|---|---|---|

| Stranding No x mm (Nom.) | Diameter mm (Nom.) | ||||||||

| 18* | 0.82 | 16×0.254 | 1.19 | 0.38 | 0.10 | 2.3 | 12 | 18.23 | 152 C |

| 16* | 1.31 | 19×0.296 | 1.48 | 0.38 | 0.10 | 2.5 | 17 | 13.42 | 152 C |

| 14 | 2.08 | 19×0.373 | 1.86 | 0.38 | 0.10 | 2.9 | 25 | 8.62 | 152 C |

| 12 | 3.31 | 19×0.47 | 2.35 | 0.38 | 0.10 | 3.4 | 37 | 5.43 | 152 C |

| 10 | 5.26 | 19×0.594 | 2.97 | 0.51 | 0.10 | 4.3 | 59 | 3.409 | 152 C |

| 8 | 8.37 | 19×0.749 | 3.75 | 0.76 | 0.13 | 5.6 | 96 | 2.144 | 152 C |

| 6 | 13.3 | 19×0.945 | 4.72 | 0.76 | 0.13 | 6.6 | 146 | 1.348 | 152 C |

| 4 | 21.15 | 19×1.19 | 5.95 | 1.02 | 0.15 | 8.4 | 233 | 0.8481 | 1000 C |

| 2 | 33.63 | 19×1.50 | 7.50 | 1.02 | 0.15 | 9.9 | 356 | 0.5335 | 1000 C |

| 1/0 | 53.48 | 37×1.36 | 9.52 | 1.27 | 0.18 | 12.5 | 567 | 0.3354 | 1000 C |

| 2/0 | 67.43 | 37×1.52 | 10.64 | 1.27 | 0.18 | 13.6 | 697 | 0.266 | 1000 C |

* Listed as TFFN

Colour : Black, White, Red, Blue, Green, Yellow, Orange, Brown, etc.

Cutting Length : 152 M (500 FT) in Coils 1000 M (3280 FT) in Drums

| Nominal cross sectional area | Number of Strands | Approx. Overall Diameter | Approx. Weight | Max DC at 20 °C | Standard Packing |

|---|---|---|---|---|---|

| mm² | No. | mm | kg/km | Ohm/km | m±5% |

| 2.5 | 7 | 2.0 | 20 | 7.41 | 2000 |

| 4 | 7 | 2.55 | 35 | 4.61 | 2000 |

| 6 | 7 | 3.1 | 50 | 3.08 | 2000 |

| 10 | 7 | 4.0 | 85 | 1.83 | 2000 |

| 16 | 7 | 5.0 | 135 | 1.15 | 2000 |

| 25 | 7 | 6.3 | 210 | 0.727 | 2000 |

| 35 | 7 | 7.4 | 300 | 0.524 | 2000 |

| 50 | 19 | 8.8 | 400 | 0.387 | 1000 |

| 70 | 19 | 10.5 | 580 | 0.268 | 1000 |

| 95 | 19 | 12.4 | 810 | 0.193 | 1000 |

| 120 | 37 | 14.0 | 1030 | 0.153 | 1000 |

| 150 | 37 | 15.5 | 1270 | 0.124 | 1000 |

| 185 | 37 | 17.4 | 1600 | 0.0991 | 1000 |

| 240 | 61 | 20.0 | 2100 | 0.0754 | 1000 |

| 300 | 61 | 22.5 | 2640 | 0.0601 | 1000 |

| 400 | 61 | 25.4 | 3400 | 0.0470 | 1000 |

| 500 | 61 | 28.5 | 4370 | 0.0366 | 1000 |

| 630 | 91 | 32.8 | 5680 | 0.0283 | 1000 |