Control Cables

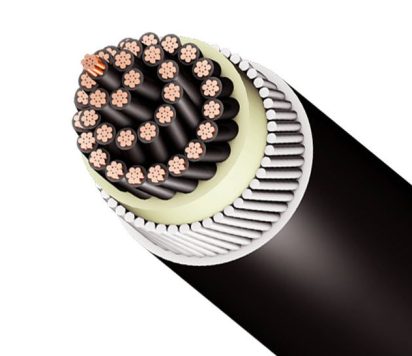

Control Cables are the cables of choice for control circuits and instrumentation used primarily for providing data and voice communications services in industrial plants and specifically in the oil and gas production industry.

At ARABIAN EXPERT Cables, we offer a range of Control Cables, with XLPE or PVC insulation, with the option of armour and/or screening. Our Control Cables are manufactured to IEC 60502-1 standards, and the conductors used in the manufacture of our Control Cables are Round Stranded Class 2 to IEC 60228. We can also provide Solid Conductors Class 1 as per IEC 60228, on special request.

Special requests can also be accommodated for the outer sheathing of Control Cables. We are able to supply fire retardant PVC, anti-termite / anti-rodent PVC, sunlight resistant PVC, and oil resistant PVC. Special sheathing materials such as low smoke halogen free (LSHF), LLDPE, and MDPE are also available on request.

Control Cables Types

PARTICULARS & GUARANTEES RELATING TO PVC INSULATING COMPOUND (TYPE A)

| Sl. No. | Description | Unit | Guaranteed Particulars |

|---|---|---|---|

| 1 | Tensile Strength and Elongation at break : | ||

| Minimum Tensile strength | N/mm² | 12.5 | |

| Minimum Elongation at break | % | 150 | |

| 2 | Low temperature bend test : | ||

| Temperature at which specimen shall not crack | °C | -15 ± 2 | |

| 3 | Low temperature elongation test : | ||

| Test temperature | °C | -15 ± 2 | |

| Minimum Elongation | % | 20 | |

| 4 | Low temperature impact test : | ||

| Test temperature | °C | – | |

| Minimum Elongation | |||

| 5 | Accelerated ageing for specified at specified temperature followed by loss of mass test : | ||

| Max. loss of mass, after ageing 7 days at 80 ± 2 °C | mg/cm² | – | |

| 6 | Accelerated ageing for specified period at specified temperature followed by tensile strength & elongation at break | ||

| Number of days ageing | Days | 7 | |

| Ageing temperature | °C | 100 ± 2 | |

| Tensile Strength after ageing : | |||

| Min. value | N/mm² | 12.5 | |

| Max. Variation | % | 25 | |

| Elongation at break after ageing | |||

| Min. value | % | 150 | |

| Max. variation from unaged value | % | 25 | |

| 7 | Pressure test at high temperature : | ||

| Test temperature | °C | 80 ± 2 | |

| Max. indentation | % | 50 | |

| 8 | Resistance to cracking : | ||

| Temperature at which specimen shall not crack | °C | 150 ± 2 | |

| 9 | Insulation resistance constant : | ||

| Min. K. value at 70 °C | M.Ohm.km | – | |

Particulars & Guarantees Relating to PVC Insulating Compound (TYPE A) & (TYPE TI1)

Particulars & Guarantees Relating to PVC Insulating Compound (SASO 1694) / Particulars & Guarantees Relating to XLPE Insulation

PVC, XLPE INSULATION

STANDARD : IEC 60502-1, SASO 1694

- REQUEST A QUOTE

- PVC

- XLPE

PARTICULARS & GUARANTEES RELATING TO PVC INSULATING COMPOUND (SASO 1694)

Sl. No. Description Unit Guaranteed Particulars 1 Tensile Strength and Elongation at break: Min Tensile strength N/mm² 12.5 Min elongation at break % 125 2 Low temperature bend test: Temperature at which specimen shall not crack °C -15 ± 2 3 Low temperature elongation test: Test temperature °C -15 ± 2 Min. Elongation % 20 4 Accelerated ageing for specified at specified period at specified temperature followed by loss of mass test: Max. loss of mass after ageing 10 days at 115 ± 2 °C mg/cm² 1.5 5 Accelerated ageing for specified period at specified temperature followed by tensile strength & elongation at break Number of Days ageing Days 10 Ageing Temperature °C 135 ± 2 Tensile Strength after ageing: Min. value N/mm² 12.5 Max. variation % 25 Elongation at break after ageing: Min. value % 125 Max. variation from unaged value % 25 6 Pressure test at high temperature: Test temperature °C 95 ± 2 Max. indentation % 50 7 Resistance to cracking Temperature at which specimen shall not crack °C 150 ± 2 8 Insulation resistance constant: Min. K. value at 20°C M.Ohm.km 180

PVC OUTER SHEATH

STANDARD : IEC 60502-1, BS 7655

- REQUEST A QUOTE

PARTICULARS & GUARANTEES RELATING TO PVC OUTER SHEATH TYPE ST2 (IEC 60502), TYPE 9 (BS 6755)

| Sl. No. | Description | Unit | Guaranteed Particulars |

|---|---|---|---|

| 1 | Tensile Strength and Elongation at break: | ||

| Min Tensile strength | N/mm² | 12.5 | |

| Min elongation at break | % | 150 | |

| 2 | Low temperature bend test: | ||

| Temperature at which specimen shall not crack | °C | -15 ± 2 | |

| 3 | Low temperature elongation test: | ||

| Test temperature | °C | -15 ± 2 | |

| Min. Elongation | % | 20 | |

| 4 | Low temperature Impact test: | ||

| Temperature at which specimen shall not crack | °C | -15 ± 2 | |

| 5 | Loss of mass after ageing for 7 days at 100 ± 2 °C | ||

| Max. loss of mass | mg/cm² | 1.5 | |

| 6 | Accelerated ageing for specified period at specified temperature followed by tensile strength & elongation at break | ||

| Number of Days ageing | 7 | ||

| Ageing Temperature | °C | 100 ± 2 | |

| Tensile Strength after ageing: | |||

| Min. value | N/mm² | 12.5 | |

| Max. variation | % | 25 | |

| Elongation at break after ageing: | |||

| Min. value | % | 150 | |

| Max. variation from unaged value | % | 25 | |

| 7 | Pressure test at high temperature: | ||

| Test temperature | °C | 90 ± 2 | |

| Max. indentation | % | 50 | |

| 8 | Heat Shock Test: | ||

| Temperature at which specimen shall not crack | °C | 150 ± 3 | |

| 9 | Insulation resistance constant: | ||

| Min. K. value at 20°C | M.Ohm.km | 0.0035 | |

| 10 | Flame Retardancy test (if required) | As per IEC 60332-1-2 (upon request) | |

CONTROL CABLES XLPE INSULATED AND PVC SHEATHED

COPPER CONDUCTORS

STANDARD IEC 60502-1

600/1000 VOLTS

- REQUEST A QUOTE

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colour Code (1): | Colour Code (2) : | Tolerance : |

|---|---|---|

| 1 Core : Red or Black 2 Core : Red, Black 3 Core : Red, Yellow, Blue 4 Core : Red, Yellow, Blue, Black 5 Cores : Red, Yellow, Blue, Black, Green Above 5 cores : Black cores with white numerals. | 1 Core : Brown or Blue 2 Core : Brown, Blue 3 Core : Brown, Black, Grey 4 Core : Blue, Brown, Black, Grey 5 Cores : Green/Yellow, Blue, Brown, Black, Grey Above 5 cores : Black cores with White numerals | Overall diameter : -2%, +8% Packing : ± 5% |

| Also available upon request : a) Solid (re) Conductors. b) Control Cables with Copper Wire Screen. c) Control Cables with one core Green/Yellow. | ||

CONTROL CABLES XLPE INSULATED AND PVC SHEATHED

COPPER CONDUCTORS

STANDARD IEC 60502-1

600/1000 VOLTS

- REQUEST A QUOTE

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colour Code (1): | Colour Code (2) : | Tolerance : |

|---|---|---|

| 1 Core : Red or Black 2 Core : Red, Black 3 Core : Red, Yellow, Blue 4 Core : Red, Yellow, Blue, Black 5 Cores : Red, Yellow, Blue, Black, Green Above 5 cores : Black cores with white numerals. | 1 Core : Brown or Blue 2 Core : Brown, Blue 3 Core : Brown, Black, Grey 4 Core : Blue, Brown, Black, Grey 5 Cores : Green/Yellow, Blue, Brown, Black, Grey Above 5 cores : Black cores with White numerals | Overall diameter : -2%, +8% Packing : ± 5% |

| Also available upon request : a) Solid (re) Conductors. b) Control Cables with Copper Wire Screen. c) Control Cables with one core Green/Yellow. | ||

CONTROL CABLES XLPE INSULATED AND PVC SHEATHED

COPPER CONDUCTORS

STANDARD IEC 60502-1

600/1000 VOLTS

- REQUEST A QUOTE

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colour Code (1): | Colour Code (2) : | Tolerance : |

|---|---|---|

| 1 Core : Red or Black 2 Core : Red, Black 3 Core : Red, Yellow, Blue 4 Core : Red, Yellow, Blue, Black 5 Cores : Red, Yellow, Blue, Black, Green Above 5 cores : Black cores with white numerals. | 1 Core : Brown or Blue 2 Core : Brown, Blue 3 Core : Brown, Black, Grey 4 Core : Blue, Brown, Black, Grey 5 Cores : Green/Yellow, Blue, Brown, Black, Grey Above 5 cores : Black cores with White numerals | Overall diameter : -2%, +8% Packing : ± 5% |

| Also available upon request : a) Solid (re) Conductors. b) Control Cables with Copper Wire Screen. c) Control Cables with one core Green/Yellow. | ||

CONTROL CABLES PVC INSULATED AND PVC SHEATHED

COPPER CONDUCTORS

STANDARD IEC 60502-1

600/1000 VOLTS

- REQUEST A QUOTE

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colour Code (1): | Colour Code (2) : | Tolerance : |

|---|---|---|

| 1 Core : Red or Black 2 Core : Red, Black 3 Core : Red, Yellow, Blue 4 Core : Red, Yellow, Blue, Black 5 Cores : Red, Yellow, Blue, Black, Green Above 5 cores : Black cores with white numerals. | 1 Core : Brown or Blue 2 Core : Brown, Blue 3 Core : Brown, Black, Grey 4 Core : Blue, Brown, Black, Grey 5 Cores : Green/Yellow, Blue, Brown, Black, Grey Above 5 cores : Black cores with White numerals | Overall diameter : -2%, +8% Packing : ± 5% |

| Also available upon request : a) Solid (re) Conductors. b) Control Cables with Copper Wire Screen. c) Control Cables with one core Green/Yellow. | ||

CONTROL CABLES PVC INSULATED AND PVC SHEATHED

COPPER CONDUCTORS

STANDARD IEC 60502-1

600/1000 VOLTS

- REQUEST A QUOTE

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colour Code (1): | Colour Code (2) : | Tolerance : |

|---|---|---|

| 1 Core : Red or Black 2 Core : Red, Black 3 Core : Red, Yellow, Blue 4 Core : Red, Yellow, Blue, Black 5 Cores : Red, Yellow, Blue, Black, Green Above 5 cores : Black cores with white numerals. | 1 Core : Brown or Blue 2 Core : Brown, Blue 3 Core : Brown, Black, Grey 4 Core : Blue, Brown, Black, Grey 5 Cores : Green/Yellow, Blue, Brown, Black, Grey Above 5 cores : Black cores with White numerals | Overall diameter : -2%, +8% Packing : ± 5% |

| Also available upon request : a) Solid (re) Conductors. b) Control Cables with Copper Wire Screen. c) Control Cables with one core Green/Yellow. | ||

CONTROL CABLES PVC INSULATED AND PVC SHEATHED

COPPER CONDUCTORS

STANDARD IEC 60502-1

600/1000 VOLTS

- REQUEST A QUOTE

Cross Sectional Area of Conductor : : 4 mm² (Round Stranded) Thickness of Insulation : 1.0 mm Conductor DC Resistance at 20°C : 4.61 Ohm/Km Thickness of copper tape screen : 0.075 mm (Applicable only for CU/PVC/CUT/PVC) Number of Cores CU/PVC/PVC CU/PVC/SWA/PVC CU/PVC/STA/PVC CU/PVC/CUT/PVC UNARMOURED STEEL WIRE ARMOUR STEEL TAPE ARMOUR COPPER TAPE SCREENED Nominal Sheath Thick. Approx. Overall Dia. Approx. Weight Pack

ingNominal Steel Wire Nominal Sheath thick. Approx. Overall dia Approx. Weight Pack

ingNominal St.tape Thick. Nominal Sheath thick. Apprx. Overall dia Apprx. Weight Pack

ingNominal Sheath Thick. Apprx. Overall Dia. Apprx. Weight Pack

ingNo. mm mm Kg/Km M mm mm mm Kg/Km M mm mm mm Kg/Km M mm mm Kg/Km M 2 1.8 16 335 2000 0.8 1.8 17 535 2000 0.2 1.8 16 425 2000 1.8 16 375 2000 3 1.8 16 400 2000 1.25 1.8 19 750 2000 0.2 1.8 17 500 2000 1.8 17 435 2000 4 1.8 18 465 2000 1.25 1.8 20 825 2000 0.2 1.8 18 575 2000 1.8 18 500 2000 5 1.8 19 550 2000 1.25 1.8 21 950 2000 0.2 1.8 20 650 2000 1.8 19 600 2000 7 1.8 20 650 2000 1.25 1.8 23 1075 2000 0.2 1.8 21 775 2000 1.8 20 700 2000 10 1.8 25 850 2000 1.6 1.8 28 1550 1000 0.2 1.8 26 1000 1000 1.8 25 925 2000 12 1.8 25 975 2000 1.6 1.8 29 1700 1000 0.2 1.8 26 1125 1000 1.8 26 1050 1000 14 1.8 27 1100 1000 1.6 1.8 30 1875 1000 0.2 1.8 27 1275 1000 1.8 27 1175 1000 16 1.8 28 1250 1000 1.6 1.8 31 2050 500 0.2 1.8 29 1425 1000 1.8 28 1325 1000 19 1.8 29 1425 1000 1.6 1.9 33 2250 500 0.2 1.8 30 1600 1000 1.8 30 1500 1000 24 1.9 34 1800 500 2.0 2.1 39 3100 500 0.2 2.0 35 2025 500 2.0 35 1900 500 27 2.0 35 2000 500 2.0 2.1 39 3275 500 0.2 2.0 36 2200 500 2.0 36 2100 500 30 2.0 36 2175 500 2.0 2.1 41 3500 500 0.2 2.1 37 2425 500 2.0 37 2275 500 37 2.1 39 2625 500 2.0 2.2 44 4050 500 0.5 2.2 42 3250 500 2.1 40 2725 500 44 2.2 44 3100 500 2.5 2.4 50 5150 500 0.5 2.4 47 3825 500 2.3 45 3225 500 48 2.3 45 3400 500 2.5 2.4 51 5450 500 0.5 2.4 48 4100 500 2.3 46 3500 500 52 2.3 47 3625 500 2.5 2.5 52 5800 500 0.5 2.4 49 4375 500 2.3 47 3750 500 61 2.4 49 4175 500 2.5 2.6 55 6475 500 0.5 2.5 52 4975 500 2.4 50 4300 500 Colour Code (1): Colour Code (2) : Tolerance : 1 Core : Red or Black

2 Core : Red, Black

3 Core : Red, Yellow, Blue

4 Core : Red, Yellow, Blue, Black

5 Cores : Red, Yellow, Blue, Black, Green

Above 5 cores : Black cores with white numerals.1 Core : Brown or Blue

2 Core : Brown, Blue

3 Core : Brown, Black, Grey

4 Core : Blue, Brown, Black, Grey

5 Cores : Green/Yellow, Blue, Brown, Black, Grey

Above 5 cores : Black cores with White numeralsOverall diameter : -2%, +8%

Packing : ± 5%Also available upon request :

a) Solid (re) Conductors.

b) Control Cables with Copper Wire Screen.

c) Control Cables with one core Green/Yellow.