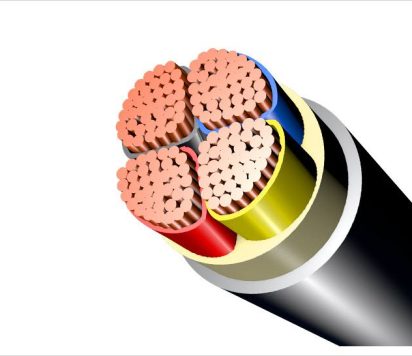

LV Cables

At ARABIAN EXPERTS Cables, we produce Low Voltage Cables in both PVC and XLPE insulations of copper and aluminium, with armoured and un-armoured designs, and in single or multi-core constructions.

The performance and load specifications of PVC and XLPE insulated cables determine the specific use of Low Voltage Cables. PVC insulated Low Voltage Cables may be used for electrical power, lighting and wiring for residential and administrative office buildings. XLPE insulated Low Voltage Cables are ideally suited to industrial applications, with an operating temperature of 90⁰C. Our Low Voltage Cables are manufactured to IEC 60502-1 specifications.

In addition to the regular range of Low Voltage Cables, we are also able to supply Low Voltage Cables with special flame retardant PVC Outer Sheathing to comply with the flame retardant test requirements outlined in IEC 60332-1, IEC 60332-3-22, IEC 60332-3-23 or IEC 60332-3-24. We can also manufacture cables with low smoke halogen free (LSHF) material (type ST8) as per IEC 60502.

LV Cables Types

| PARTICULARS & GUARANTEES RELATING TO PVC INSULATING COMPOUND (TYPE A) |

|---|

| Sl. No. | Description | Unit | Guaranteed Particulars |

|---|---|---|---|

| 1 | Tensile Strength and Elongation at break: | ||

| Min Tensile strength | N/mm² | 12.5 | |

| Min elongation at break | % | 150 | |

| 2 | Low temperature bend test: | ||

| Temperature at which specimen shall not crack | °C | -15±2 | |

| 3 | Low temperature elongation test: | ||

| Test temperature | °C | -15±2 | |

| Min. Elongation | % | 20 | |

| 4 | Low temperature Impact test: | ||

| Test temperature | °C | – | |

| Min. Elongation | |||

| 5 | Accelerated ageing for specified at specified temperature followed by loss of mass test: | ||

| Max. loss of mass after ageing 7 days at 80 ± 2 °C | mg/cm² | – | |

| 6 | Accelerated ageing for specified period specified temperature followed by tensile strength & elongation at break | ||

| Number of Days ageing | Days | 7 | |

| Ageing Temperature | °C | 100 ± 2 | |

| Tensile Strength after ageing: | |||

| Min. value | N/mm² | 12.5 | |

| Max. variation | % | 25 | |

| Elongation at break after ageing: | |||

| Min. value | % | 150 | |

| Max. variation from unaged value | % | 25 | |

| 7 | Pressure test at high temperature: | ||

| Test temperature | °C | 80 ± 2 | |

| Max. indentation | % | 50 | |

| 8 | Resistance to cracking | ||

| Temperature at which specimen shall not crack | °C | 150 ± 2 | |

| 9 | Insulation resistance constant: | ||

| Min. K. value at 70°C | M.Ohm.km | ||

| PARTICULARS & GUARANTEES RELATING TO XLPE INSULATION |

|---|

| Sl. No. | Description | Unit | Guaranteed Particulars |

|---|---|---|---|

| 1 | Tensile Strength and Elongation at break: | ||

| Min Tensile strength | N/mm² | 12.5 | |

| Min elongation at break | % | 200 | |

| 2 | Accelerated ageing for specified period specified temperature followed by tensile strength & elongation at break | ||

| Number of Days ageing | Days | 7 | |

| Ageing Temperature | °C | 135 ± 2 | |

| Max. variation of tensile strength from unaged specimen | % | ± 25 | |

| Max. variation of elongation from unaged specimen | % | ± 25 | |

| 3 | Hot Set Test: | ||

| Treatment | |||

| – Temperature | °C | 200 ± 3 | |

| – Time under load | Minutes | 15 | |

| – Mechanical stress | N/cm² | 20 | |

| Max. elongation under load | % | 175 | |

| Max. permanent elongation after cooling | % | 15 | |

| 4 | Water Absorption: | ||

| Treatment | |||

| – Temperature | °C | 85 ± 2 | |

| – Duration | Days | 14 | |

| Max. variation of mass | mg/cm² | 1.0 | |

| 5 | Maximum permissible shrinkage: | ||

| Treatment | |||

| – Temperature | °C | 130 ± 3 | |

| – Duration | Hours | 1 | |

| Maximum permissible shrinkage: | % | 4 | |

| 6 | Insulation Resistance constant | ||

| (Ki) at maximum rated temperature (90°C) | M.Ohm.km | 3.67 | |

| 7 | Volume Resistivity at maximum rated temperature (90°C) | Ohm.cm | 1012 |

- PVC OUTER SHEATH

- STANDARD : IEC 60502-1, BS 7655

PARTICULARS & GUARANTEES RELATING TO PVC OUTER SHEATH TYPE ST2 (IEC 60502), TYPE 9 (BS 7655)

| Sl. No. | Description | Unit | Guaranteed Particulars |

|---|---|---|---|

| 1 | Tensile Strength and Elongation at break: | ||

| Min Tensile strength | N/mm² | 12.5 | |

| Min elongation at break | % | 150 | |

| 2 | Low temperature bend test: | ||

| Temperature at which specimen shall not crack | °C | -15 ± 2 | |

| 3 | Low temperature elongation test: | ||

| Test temperature | °C | -15 ± 2 | |

| Min. Elongation | % | 20 | |

| 4 | Low temperature Impact test: | ||

| Temperature at which specimen shall not crack | °C | -15 ± 2 | |

| 5 | Loss of mass: | ||

| After ageing for 7 days at 100 ± 2 °C | |||

| Max. loss of mass | mg/cm² | 1.5 | |

| 6 | Accelerated ageing for specified period at specified temperature followed by tensile strength & elongation at break test | ||

| Number of Days ageing | 7 | ||

| Ageing Temperature | °C | 100 ± 2 | |

| Tensile Strength after ageing: | |||

| Min. value | N/mm² | 12.5 | |

| Max. variation | % | 25 | |

| Elongation at break after ageing: | |||

| Min. value | % | 150 | |

| Max. variation from unaged value | % | 25 | |

| 7 | Pressure test at high temperature: | ||

| Test temperature | °C | 90 ± 2 | |

| Max. indentation | % | 50 | |

| 8 | Heat Shock Test: | ||

| Temperature at which specimen shall not crack | % | 150 ± 2 | |

| 9 | Insulation resistance constant: | ||

| Min. K. value at 20°C | M.Ohm.km | 0.0035 | |

| 10 | Flame Retardancy test (if required) | As per IEC 60332-1-2(upon request | |

XLPE INSULATED, PVC SHEATHED CABLES

ALUMINIUM CONDUCTORS

STANDARD : IEC 60502-1

600/1000 VOLTS

- REQUEST A QUOTE

- UNARMOURED

- ALUMINIUM/STEEL WIRE ARMOURED

- ALUMINIUM/STEEL TAPE ARMOURED

|

|

|

|

|

|

| Colour Code ( 1 ) | Colour Code ( 2 ) | Tolerance range : | |

|---|---|---|---|

| rm : Round Stranded sm : Sectoral Stranded | 1 core : Black (Red on request) 2 cores : Red, Black 3 Cores : Red, Yellow, Blue | 1 core : Brown or Blue 2 cores : Brown, Blue 3 cores : Brown, Black, Grey | Overall diameter -2%, +8% Packing ±5% |

Single core cables are Aluminium Armoured as per IEC 60502-1 recommendation. For sectoral conductors, number of wires mentioned is minimum number of wires in accordance with IEC 228 | |||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

| Colour Code ( 1 ) | Colour Code ( 2 ) | Tolerance range : | |

|---|---|---|---|

| re : Round Solid rm : Round Stranded sm : Sectoral Stranded Ph : Phase Conductor Ne : Neutral Conductor | 3 1/2 Cores : Red, Yellow, Blue, Black 4 cores : Red, Yellow, Blue, Black | 3 1/2 Cores : Blue, Brown, Black, Grey 4 cores :Blue, Brown, Black, Grey | Overall diameter -2%, +8% Packing ±5% |

For 3 1/2 cores, neutral conductors are round stranded. | |||

|

|

|

|

| Colour Code ( 1 ) | Colour Code ( 2 ) | |

|---|---|---|

| rm : Round Stranded | 1 core : Black (Red on request) 2 cores : Red, Black | 1 Core : Brown or Blue 2 Cores : Brown, Blue |

Single cores cables are Aluminium Wire Armoured as per BS 6346 recommendation. | ||

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colour Code ( 1 ) | Colour Code ( 2 ) | |

|---|---|---|

| rm : Round Stranded sm : Sectoral Stranded Ph : Phase Ne : Neutral | 3 cores : Red, Yellow, Blue 3 1/2 cores : Red, Yellow, Blue, Black | 3 Cores : Brown, Black, Grey 3 1/2 Cores : Blue, Brown, Black, Grey |

| For sectoral conductors, number of wires mentioned are minimum number of wires in accordance with BS EN 60228. | ||

|

|

|

|

XLPE INSULATED, PVC SHEATHED CABLES

COPPER CONDUCTORS

STANDARD : BS 5467

0.6 / 1 kV

- REQUEST A QUOTE

|

|

|

|

| Colour Code ( 1 ) | Colour Code ( 2 ) | |

|---|---|---|

| rm : Round Stranded | 1 core : Black (Red on request) 2 cores : Red, Black | 1 core : Brown or Blue 2 cores : Brown, Blue |

| ||

|

|

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Colour Code ( 1 ) | Colour Code ( 2 ) | |

|---|---|---|

| rm : Round Stranded sm : Sectoral Stranded Ph : Phase Ne : Neutral | 3 cores : Red, Yellow, Blue 3 1/2 cores : Red, Yellow, Blue, Black | 3 cores : Brown, Black, Grey 3 1/2 cores : Blue, Brown, Black, Grey |

For 31/2 cores, above 35 mm² size of phase, neutral conductors are round stranded. For sectoral conductors, number of wires mentioned are minimum number of wires in accordance with BS EN 60228. | ||

|

|

|

|

PVC Insulation TYPE A (IEC 60502-1), PVC Insulation TYPE TI1(BS EN 50363)

PVC Insulation as per SASO 1694, XLPE Insulation (IEC 60502-1, BS 5467)

PVC Sheath TYPE ST2 (IEC 60502), TYPE 9 (BS 7655).

PVC Insulation PVC Sheathed Cables (IEC 60502-1), Copper.

PVC INSULATED, PVC SHEATED CABLES

COPPER CONDUCTORS

STANDARD : IEC 60502-1

600/ 1000 Volts

- REQUEST A QUOTE

- UNARMOURED

- ALUMINIUM/STEEL WIRE ARMOURED

- ALUMINIUM/STEEL TAPE ARMOURED

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 1×1.5 re 1 1.38 0.8 1×1.5 rm 7 1.56 0.8 1×2.5 re 1 1.78 0.8 1×2.5 rm 7 2.01 0.8 1×4 re 1 2.25 1.0 1×4 rm 7 2.55 1.0 1×6 re 1 2.76 1.0 1×6 rm 7 3.12 1.0 1×10 re 1 3.57 1.0 1×10 rm 7 4.01 1.0 1×16 rm 7 5.03 1.0 1×25 rm 7 6.3 1.2 1×35 rm 7 7.44 1.2 1×50 rm 19 8.8 1.4 1×70 rm 19 10.6 1.4 1×95 rm 19 12.4 1.6 1×120 rm 37 14 1.6 1×150 rm 37 15.5 1.8 1×185 rm 37 17.4 2.0 1×240 rm 61 20 2.2 1×300 rm 61 22.5 2.4 1×400 rm 61 25.4 2.6 1×500 rm 61 28.5 2.8 1×630 rm 91 32.8 2.8 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.4 6 55 1000 1.4 6 55 1000 1.4 7 65 1000 1.4 7 70 1000 1.4 7 90 1000 1.4 8 95 1000 1.4 8 110 1000 1.4 8 120 1000 1.4 9 155 1000 1.4 9 165 1000 1.4 10 230 1000 1.4 12 335 1000 1.4 13 440 1000 1.4 15 575 1000 1.4 17 785 1000 1.5 19 1075 1000 1.5 21 1325 1000 1.6 23 1600 1000 1.7 25 2000 1000 1.8 28 2600 1000 1.9 32 3250 500 2.0 35 4150 500 2.1 39 5250 500 2.2 43 6700 500 CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 2×1.5 re 1 1.38 0.8 2×1.5 rm 7 1.56 0.8 2×2.5 re 1 1.78 0.8 2×2.5 rm 7 2.01 0.8 2×4 re 1 2.25 1.0 2×4 rm 7 2.55 1.0 2×6 re 1 2.76 1.0 2×6 rm 7 3.12 1.0 2×10 re 1 3.57 1.0 2×10 rm 7 4.01 1.0 2×16 rm 7 5.03 1.0 2×25 rm 7 6.3 1.2 2×35 rm 7 7.44 1.2 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 12 200 1000 1.8 13 200 1000 1.8 13 225 1000 1.8 14 275 1000 1.8 15 325 1000 1.8 16 350 1000 1.8 16 375 1000 1.8 17 400 1000 1.8 18 500 1000 1.8 19 550 1000 1.8 21 725 1000 1.8 24 1025 1000 1.8 26 1300 1000 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : re : Round Solid

rm : Round Stranded1 core : Black (Red on request)

2 cores : Red, Black1 core : Brown or Blue

2 core : Brown, BlueOverall diameter -2%, +8%

Packing ±5%

Single core cables are Aluminium Armoured as per IEC 60502-1 recommendation.

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 3×1.5 re 1 1.38 0.8 3×1.5 rm 7 1.56 0.8 3×2.5 re 1 1.78 0.8 3×2.5 rm 7 2.01 0.8 3×4 re 1 2.25 1.0 3×4 rm 7 2.55 1.0 3×6 re 1 2.76 1.0 3×6 rm 7 3.12 1.0 3×10 re 1 3.57 1.0 3×10 rm 7 4.01 1.0 3×16 rm 7 5.03 1.0 3×25 rm 7 6.3 1.2 3×35 rm 7 7.44 1.2 3×50 sm 6 – 1.4 3×70 sm 12 – 1.4 3×95 sm 15 – 1.6 3×120 sm 18 – 1.6 3×150 sm 18 – 1.8 3×185 sm 30 – 2.0 3×240 sm 34 – 2.2 3×300 sm 34 – 2.4 3×400 sm 53 – 2.6 3×500 sm 53 – 2.8 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 13 225 1000 1.8 13 225 1000 1.8 14 275 1000 1.8 14 285 1000 1.8 16 375 1000 1.8 16 400 1000 1.8 17 450 1000 1.8 18 475 1000 1.8 19 600 1000 1.8 19 650 1000 1.8 22 875 1000 1.8 25 1275 1000 1.8 28 1500 1000 1.8 29 1850 1000 2.0 32 2525 500 2.1 36 3400 500 2.2 39 4150 500 2.3 44 5125 500 2.5 48 6350 500 2.7 54 8225 500 2.9 59 10200 500 3.1 67 12875 500 3.4 74 16340 500 CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness Ph Ne Ph Ne Ph Ne 3×10 rm+6 7 7 4.01 3.12 1.0 1.0 3×16 rm+10 7 7 5.03 4.01 1.0 1.0 3×25 rm+16 7 7 6.3 5.03 1.2 1.0 3×35 sm+16 6 7 – 5.03 1.2 1.0 3×50 sm+25 6 7 – 6.30 1.4 1.2 3×70 sm+35 12 7 – 7.44 1.4 1.2 3×95 sm+50 15 19 – 8.80 1.6 1.4 3×120 sm+70 18 19 – 10.60 1.6 1.4 3×150 sm+70 18 19 – 10.60 1.8 1.4 3×185 sm+95 30 19 – 12.40 2.0 1.6 3×240 sm+120 34 37 – 14.00 2.2 1.6 3×300 sm+150 34 37 – 15.50 2.4 1.8 3×400 sm+185 53 37 – 17.40 2.6 2.0 3×500 sm+240 53 61 – 20.00 2.8 2.2 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 21 730 1000 1.8 23 1000 1000 1.8 27 1450 1000 1.8 27 1600 1000 1.9 31 2150 1000 2.0 35 2950 500 2.2 39 3975 500 2.3 43 4975 500 2.4 47 5925 500 2.6 52 7425 500 2.8 58 9575 500 3.0 64 11850 250 3.2 72 15025 250 3.5 79 19025 250 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : re : Round Solid

rm : Round Stranded

sm : Sectoral Stranded

Ph : Phase

Ne : Neutral3 cores : Red, Yellow, Blue

31/2 cores : Red, Yellow, Blue, Black3 Cores :Brown, Black, Grey

3 1/2 Cores : Blue, Brown, Black, GreyOverall diameter -2%, +8%

Packing ±5%

For 31/2 core, neutral conductors are round stranded.

For sectoral conductors, number of wires mentioned is minimum number of wires in accordance with IEC 228.

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 4×1.5 re 1 1.38 0.8 4×1.5 rm 7 1.56 0.8 4×2.5 re 1 1.78 0.8 4×2.5 rm 7 2.01 0.8 4×4 re 1 2.25 1.0 4×4 rm 7 2.55 1.0 4×6 re 1 2.76 1.0 4×6 rm 7 3.12 1.0 4×10 re 1 3.57 1.0 4×10 rm 7 4.01 1.0 4×16 rm 7 5.03 1.0 4×25 rm 7 6.3 1.2 4×35 sm 6 – 1.2 4×50 sm 6 – 1.4 4×70 sm 12 – 1.4 4×95 sm 15 – 1.6 4×120 sm 18 – 1.6 4×150 sm 18 – 1.8 4×185 sm 30 – 2.0 4×240 sm 34 – 2.2 4×300 sm 34 – 2.4 4×400 sm 53 – 2.6 4×500 sm 53 – 2.8 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 14 250 1000 1.8 14 275 1000 1.8 15 325 1000 1.8 15 325 1000 1.8 17 450 1000 1.8 18 475 1000 1.8 18 550 1000 1.8 19 575 1000 1.8 20 750 1000 1.8 21 800 1000 1.8 24 1100 1000 1.8 28 1600 1000 1.8 28 1800 1000 1.9 32 2400 500 2.1 36 3275 500 2.2 41 4425 500 2.4 45 5475 500 2.5 49 6700 500 2.7 55 8350 500 2.9 61 10765 500 3.1 67 13350 250 3.4 76 17000 250 3.6 83 21425 250 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : re : Round Solid

rm : Round Stranded

sm : Sectoral Stranded4 cores : Red, Yellow, Blue, Black 4 cores :Blue, Brown, Black, Grey Overall diameter -2%, +8%

Packing ±5%

For sectoral conductors, number of wires mentioned is minimum of wires in accordance with IEC 228.

PVC Insulation TYPE A (IEC 60502-1), PVC Insulation TYPE TI1(BS EN 50363)

PVC Insulation as per SASO 1694, XLPE Insulation (IEC 60502-1, BS 5467)

PVC Sheath TYPE ST2 (IEC 60502), TYPE 9 (BS 7655).

PVC Insulation PVC Sheathed Cables (IEC 60502-1), Copper.

PVC Insulation PVC Sheathed Cables (IEC 60502-1), Aluminium.

PVC INSULATED , PVC SHEATHED CABLES

ALUMINIUM CONDUCTORS

STANDARD : IEC 60502-1

600/1000 VOLTS

- UNARMOURED

- ALUMINIUM/STEEL WIRE ARMOURED

- ALUMINIUM/STEEL TAPE ARMOURED

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 1×16 rm 7 4.98 1.0 1×25 rm 7 6.3 1.2 1×35 rm 7 7.41 1.2 1×50 rm 19 8.75 1.4 1×70 rm 19 10.55 1.4 1×95 rm 19 12.4 1.6 1×120 rm 37 14 1.6 1×150 rm 37 15.47 1.8 1×185 rm 37 17.36 2.0 1×240 rm 61 19.89 2.2 1×300 rm 61 22.23 2.4 1×400 rm 61 25.2 2.6 1×500 rm 61 28.62 2.8 1×630 rm 91 32.56 2.8 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.4 10 135 1000 1.4 12 185 1000 1.4 13 225 1000 1.4 15 300 1000 1.4 17 375 1000 1.5 19 500 1000 1.5 21 600 1000 1.6 23 725 1000 1.7 25 900 1000 1.8 28 1150 1000 1.9 31 1400 1000 2.0 35 1750 500 2.1 39 2200 500 2.2 43 2725 500

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 2×16 rm 7 4.98 1.0 2×25 rm 7 6.3 1.2 2×35 rm 7 7.41 1.2 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 20 525 1000 1.8 24 725 1000 1.8 26 875 1000 CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 3×16 rm 7 4.98 1.0 3×25 rm 7 6.3 1.2 3×35 rm 7 7.41 1.2 3×50 sm 6 – 1.4 3×70 sm 12 – 1.4 3×95 sm 15 – 1.6 3×120 sm 15 – 1.6 3×150 sm 15 – 1.8 3×185 sm 30 – 2.0 3×240 sm 30 – 2.2 3×300 sm 30 – 2.4 3×400 sm 53 – 2.6 3×500 sm 53 – 2.8 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 22 600 1000 1.8 25 825 1000 1.8 28 875 1000 1.8 29 1000 1000 2.0 32 1275 500 2.1 36 1675 500 2.2 39 1950 500 2.3 44 2400 500 2.5 48 2925 500 2.7 54 3775 500 2.9 59 4575 500 3.1 67 5725 250 3.4 74 7175 250 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : rm : Round Stranded

sm : Sectoral Stranded1 core : Black (Red on request)

2 cores : Red, Black

3 Cores : Red, Yellow, Blue1 core : Brown or Blue

2 cores : Brown, Blue

3 cores : Brown, Black, GreyOverall diameter -2%, +8%

Packing ±5%

Single core cables are Aluminium Armoured as per IEC 60502-1 recommendation.

For sectoral conductors, number of wires mentioned is minimum number of wires in accordance with IEC 228CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness Ph Ne Ph Ne Ph Ne 3×25 rm+16 7 7 6.3 4.98 1.2 1.0 3×35 sm+16 6 7 – 4.98 1.2 1.0 3×50 sm+25 6 7 – 6.30 1.4 1.2 3×70 sm+35 12 7 – 7.41 1.4 1.2 3×95 sm+50 15 19 – 8.75 1.6 1.4 3×120 sm+70 15 19 – 10.55 1.6 1.4 3×150 sm+70 15 19 – 10.55 1.8 1.4 3×185 sm+95 30 19 – 12.40 2.0 1.6 3×240 sm+120 30 37 – 14.00 2.2 1.6 3×300 sm+150 30 37 – 15.47 2.4 1.8 3×400 sm+185 53 37 – 17.36 2.6 2.0 3×500 sm+240 53 61 – 19.89 2.8 2.2 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 27 900 1000 1.8 27 875 1000 1.9 31 1150 500 2.0 34 1475 500 2.2 39 1950 500 2.3 43 2375 500 2.4 47 2800 500 2.6 52 3450 500 2.8 58 4400 500 3.0 64 5375 250 3.2 72 6775 250 3.5 79 8400 250

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 4×16 rm 7 4.98 1.0 4×25 rm 7 6.3 1.2 4×35 sm 6 – 1.2 4×50 sm 6 – 1.4 4×70 sm 12 – 1.4 4×95 sm 15 – 1.6 4×120 sm 15 – 1.6 4×150 sm 15 – 1.8 4×185 sm 30 – 2.0 4×240 sm 30 – 2.2 4×300 sm 30 – 2.4 4×400 sm 53 – 2.6 4×500 sm 53 – 2.8 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 23 700 1000 1.8 28 1000 1000 1.8 28 925 1000 1.9 32 1250 500 2.1 36 1600 500 2.2 41 2100 500 2.4 45 2550 500 2.5 49 3075 500 2.7 55 3800 500 2.9 61 4825 500 3.1 67 5875 250 3.4 76 7475 250 3.6 83 9225 250 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : re : Round Solid

rm : Round Stranded

sm : Sectoral Stranded

Ph : Phase Conductor

Ne : Neutral Conductor3 1/2 Cores : Red, Yellow, Blue, Black

4 cores : Red, Yellow, Blue, Black3 1/2 Cores : Blue, Brown, Black, Grey

4 cores :Blue, Brown, Black, GreyOverall diameter -2%, +8%

Packing ±5%

For 3 1/2 cores, neutral conductors are round stranded.

PVC Insulation TYPE A (IEC 60502-1), PVC Insulation TYPE TI1(BS EN 50363)

PVC Insulation as per SASO 1694, XLPE Insulation (IEC 60502-1, BS 5467)

PVC Sheath TYPE ST2 (IEC 60502), TYPE 9 (BS 7655).

PVC Insulation PVC Sheathed Cables (IEC 60502-1), Copper.

PVC Insulation PVC Sheathed Cables (IEC 60502-1), Aluminium.

XLPE Insulated PVC Sheathed Cables (IEC 60502-1), Copper.

XLPE INSULATED, PVC SHEATHED CABLES

COPPER CONDUCTORS

STANDARD : IEC 60502-1

600/1000 VOLTS

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 1×1.5 re 1 1.38 0.7 1×1.5 rm 7 1.56 0.7 1×2.5 re 1 1.78 0.7 1×2.5 rm 7 2.01 0.7 1×4 re 1 2.25 0.7 1×4 rm 7 2.55 0.7 1×6 re 1 2.76 0.7 1×6 rm 7 3.12 0.7 1×10 rm 7 4.01 0.7 1×16 rm 7 5.03 0.7 1×25 rm 7 6.3 0.9 1×35 rm 7 7.44 0.9 1×50 rm 19 8.8 1.0 1×70 rm 19 10.6 1.1 1×95 rm 19 12.4 1.1 1×120 rm 37 14 1.2 1×150 rm 37 15.5 1.4 1×185 rm 37 17.4 1.6 1×240 rm 61 20 1.7 1×300 rm 61 22.5 1.8 1×400 rm 61 25.4 2.0 1×500 rm 61 28.5 2.2 1×630 rm 91 32.8 2.4 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.4 6 45 1000 1.4 6 50 1000 1.4 6 60 1000 1.4 7 60 1000 1.4 7 75 1000 1.4 7 80 1000 1.4 7 95 1000 1.4 8 100 1000 1.4 9 145 1000 1.4 10 200 1000 1.4 11 300 1000 1.4 13 400 1000 1.4 14 525 1000 1.4 16 725 1000 1.5 18 1000 1000 1.5 20 1225 1000 1.6 22 1500 1000 1.6 24 1875 1000 1.7 27 2450 1000 1.8 30 3050 1000 1.9 34 3900 500 2.0 37 4975 500 2.2 42 6425 500 CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 2×1.5 re 1 1.38 0.7 2×1.5 rm 7 1.56 0.7 2×2.5 re 1 1.78 0.7 2×2.5 rm 7 2.01 0.7 2×4 re 1 2.25 0.7 2×4 rm 7 2.55 0.7 2×6 re 1 2.76 0.7 2×6 rm 7 3.12 0.7 2×10 rm 7 4.01 0.7 2×16 rm 7 5.03 0.7 2×25 rm 7 6.3 0.9 2×35 rm 7 7.44 0.9 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 12 175 1000 1.8 13 200 1000 1.8 13 225 1000 1.8 13 225 1000 1.8 14 275 1000 1.8 14 275 1000 1.8 15 325 1000 1.8 16 350 1000 1.8 17 475 1000 1.8 19 650 1000 1.8 23 925 1000 1.8 25 1200 1000 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : re : Round Solid

rm : Round Stranded1 core : Black (Red on request)

2 cores : Red, Black1 core : Brown or Blue

2 core : Brown, BlueOverall diameter -2%, +8%

Packing ±5%

Single core cables are Aluminium Armoured as per IEC 60502-1 recommendation.

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 3×1.5 re 1 1.38 0.7 3×1.5 rm 7 1.56 0.7 3×2.5 re 1 1.78 0.7 3×2.5 rm 7 2.01 0.7 3×4 re 1 2.25 0.7 3×4 rm 7 2.55 0.7 3×6 re 1 2.76 0.7 3×6 rm 7 3.12 0.7 3×10 rm 7 4.01 0.7 3×16 rm 7 5.03 0.7 3×25 rm 7 6.3 0.9 3×35 rm 7 7.44 0.9 3×50 sm 6 – 1.0 3×70 sm 12 – 1.1 3×95 sm 15 – 1.1 3×120 sm 18 – 1.2 3×150 sm 18 – 1.4 3×185 sm 30 – 1.6 3×240 sm 34 – 1.7 3×300 sm 34 – 1.8 3×400 sm 53 – 2.0 3×500 sm 53 – 2.2 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 13 200 1000 1.8 13 210 1000 1.8 13 250 1000 1.8 14 275 1000 1.8 14 325 1000 1.8 15 325 1000 1.8 15 400 1000 1.8 16 400 1000 1.8 18 575 1000 1.8 20 800 1000 1.8 24 1150 1000 1.8 27 1375 1000 1.8 27 1675 1000 1.9 31 2350 500 2.0 34 3150 500 2.1 37 3875 500 2.3 42 4825 500 2.4 46 5950 500 2.6 51 7725 500 2.8 56 9575 500 3.1 64 12175 250 3.3 71 15500 250 CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness Ph Ne Ph Ne Ph Ne 3×300 sm+150 34 37 – 15.50 1.8 1.4 3×400 sm+185 53 37 – 17.40 2.0 1.6 3×500 sm+240 53 61 – 20.00 2.2 1.7 3×10 rm+6 7 7 4.01 3.12 0.7 0.7 3×16 rm+10 7 7 5.03 4.01 0.7 0.7 3×25 rm+16 7 7 6.3 5.03 0.9 0.7 3×35 sm+16 6 7 – 5.03 0.9 0.7 3×50 sm+25 6 7 – 6.30 1.0 0.9 3×70 sm+35 12 7 – 7.44 1.1 0.9 3×95 sm+50 15 19 – 8.80 1.1 1.0 3×120 sm+70 18 19 – 10.60 1.2 1.1 3×150 sm+70 18 19 – 10.60 1.4 1.1 3×185 sm+95 30 19 – 12.40 1.6 1.1 3×240 sm+120 34 37 – 14.00 1.7 1.2 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 2.9 61 11150 250 3.1 68 14500 250 3.4 76 18050 250 1.8 19 640 1000 1.8 22 900 1000 1.8 25 1325 1000 1.8 25 1475 1000 1.8 29 1950 1000 1.9 33 2750 500 2.1 37 3675 500 2.2 40 4600 500 2.3 45 5550 500 2.5 50 6975 500 2.7 55 9275 500 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : re : Round Solid

rm : Round Stranded

sm : Sectoral Stranded

Ph : Phase

Ne : Neutral3 cores : Red, Yellow, Blue

31/2 cores : Red, Yellow, Blue, Black3 Cores :Brown, Black, Grey

3 1/2 Cores : Blue, Brown, Black, GreyOverall diameter -2%, +8%

Packing ±5%

For 31/2 core, neutral conductors are round stranded.

For sectoral conductors, number of wires mentioned is minimum number of wires in accordance with IEC 228.

CABLE CORE(S) Nominal Area No or wires Approx Conductor Diameter Nominal Insulation thickness mm² No. mm mm 4×1.5 re 1 1.38 0.7 4×1.5 rm 7 1.56 0.7 4×2.5 re 1 1.78 0.7 4×2.5 rm 7 2.01 0.7 4×4 re 1 2.25 0.7 4×4 rm 7 2.55 0.7 4×6 re 1 2.76 0.7 4×6 rm 7 3.12 0.7 4×10 rm 7 4.01 0.7 4×16 rm 7 5.03 0.7 4×25 rm 7 6.3 0.9 4×35 sm 6 – 0.9 4×50 sm 6 – 1.0 4×70 sm 12 – 1.1 4×95 sm 15 – 1.1 4×120 sm 18 – 1.2 4×150 sm 18 – 1.4 4×185 sm 30 – 1.6 4×240 sm 34 – 1.7 4×300 sm 34 – 1.8 4×400 sm 53 – 2.0 4×500 sm 53 – 2.2 UNARMOURED Nominal Sheath thickness Approx. Overall diameter Approx. Weight Packing mm mm Kg/Km meters 1.8 13 230 1000 1.8 14 250 1000 1.8 14 300 1000 1.8 15 300 1000 1.8 15 375 1000 1.8 16 400 1000 1.8 17 475 1000 1.8 17 500 1000 1.8 20 700 1000 1.8 22 975 1000 1.8 26 1450 1000 1.8 26 1650 1000 1.9 30 2175 1000 2.0 34 3050 500 2.1 38 4100 500 2.3 43 5125 500 2.4 47 6300 500 2.6 52 7825 500 2.8 58 10150 500 3.0 64 12575 500 3.3 73 16075 250 3.5 80 20375 250 Colour Code ( 1 ) Colour Code ( 2 ) Tolerance range : re : Round Solid

rm : Round Stranded

sm : Sectoral Stranded4 cores : Red, Yellow, Blue, Black 4 cores :Blue, Brown, Black, Grey Overall diameter -2%, +8%

Packing ±5%

PVC Insulation TYPE A (IEC 60502-1), PVC Insulation TYPE TI1(BS EN 50363)

PVC Insulation as per SASO 1694, XLPE Insulation (IEC 60502-1, BS 5467)

PVC Sheath TYPE ST2 (IEC 60502), TYPE 9 (BS 7655).

PVC Insulation PVC Sheathed Cables (IEC 60502-1), Copper.

PVC Insulation PVC Sheathed Cables (IEC 60502-1), Aluminium.

XLPE Insulated PVC Sheathed Cables (IEC 60502-1), Copper.

XLPE Insulated PVC Sheathed Cables (IEC 60502-1), Aluminium.

PVC Insulated PVC Sheathed Cables (BS 6346), Copper.

XLPE Insulated, PVC Sheathed Cables (BS 5467), Copper.

Electrical Charasteristics

PVC INSULATED, PVC SHEATHED CABLES

COPPER CONDUCTORS

600/1000 VOLTS

LOW VOLTAGE SINGLE CORE CABLE (IN TREFOIL FORMATION)

LINEAR RESISTANCE, REACTANCE AND VOLTAGE DROP

PVC INSULATED (85°C) COPPER CONDUCTOR

SIZE R (DC) R (DC) R (AC) X Z VD mm2 20 85 85 85 1.5 12.1 15.19 15.19 0.165 15.19 21.22 2.5 7.41 9.30 9.30 0.149 9.30 13.04 4 4.61 5.79 5.79 0.143 5.79 8.17 6 3.08 3.87 3.87 0.134 3.87 5.5 10 1.83 2.3 2.3 0.132 2.3 3.32 16 1.15 1.444 1.444 0.124 1.449 2.13 25 0.727 0.913 0.913 0.121 0.921 1.39 35 0.524 0.658 0.658 0.115 0.668 1.031 50 0.387 0.486 0.467 0.111 0.499 0.79 70 0.268 0.336 0.337 0.105 0.353 0.576 95 0.193 0.242 0.244 0.103 0.265 0.445 120 0.153 0.192 0.194 0.100 0.218 0.373 150 0.124 0.156 0.158 0.100 0.187 0.323 185 0.0991 0.1244 0.1272 0.099 0.161 0.279 240 0.0754 0.0947 0.0978 0.097 0.138 0.236 300 0.0601 0.0754 0.0800 0.096 0.124 0.210 400 0.0470 0.0590 0.0626 0.094 0.113 0.184 500 0.0366 0.0459 0.0504 0.092 0.105 0.165 630 0.0283 0.0355 0.0413 0.091 0.100 0.152 LOW VOLTAGE MULTI CORE CABLE

LINEAR RESISTANCE, REACTANCE AND VOLTAGE DROP

PVC INSULATED (85°C) COPPER CONDUCTOR

SIZE R (DC) R (DC) R (AC) X Z VD mm2 20 85 85 85 1.5 12.1 15.19 15.19 0.165 15.19 21.22 2.5 7.41 9.30 9.30 0.143 9.30 13.04 4 4.61 5.79 5.79 0.132 5.79 8.16 6 3.08 3.87 3.87 0.121 3.87 5.49 10 1.83 2.30 2.30 0.109 2.30 3.3 16 1.15 1.444 1.444 0.106 1.448 2.11 25 0.727 0.913 0.913 0.103 0.919 1.37 35 0.524 0.658 0.658 0.098 0.666 1.014 50 0.387 0.486 0.487 0.098 0.496 0.777 70 0.268 0.336 0.337 0.095 0.351 0.566 95 0.193 0.242 0.244 0.093 0.261 0.435 120 0.153 0.192 0.194 0.091 0.214 0.363 150 0.124 0.156 0.158 0.091 0.182 0.314 185 0.0991 0.1244 0.1272 0.091 0.1564 0.271 240 0.0754 0.0947 0.0978 0.090 0.1329 0.229 300 0.0601 0.0754 0.0800 0.090 0.1204 0.204 400 0.0470 0.0590 0.0626 0.089 0.1088 0.179 500 0.0366 0.0459 0.0504 0.088 0.1014 0.161 630 0.0283 0.0355 0.0413 0.088 0.0972 0.149 R(DC) :

20Direct Current Resistance at 20°C, Ohm/Km X : Reactance, Ohm / Km R(DC) :

85Direct Current Resistance at 90°C, Ohm/Km Z : Impedance, Ohm / Km R(AC) :

85Alternating Current Resistance at 90°C, Ohm/Km VD : Voltage Drop (Phase to Phase), V/A.Km XLPE INSULATED, PVC SHEATHED CABLES

COPPER CONDUCTORS

600/1000 VOLTS

LOW VOLTAGE SINGLE CORE CABLE (IN TREFOIL FORMATION)

LINEAR RESISTANCE, REACTANCE AND VOLTAGE DROP

XLPE INSULATED (90°C) COPPER CONDUCTOR

SIZE R (DC) R (DC) R (AC) X Z VD mm2 20 90 90 90 1.5 12.1 15.43 15.43 0.165 15.43 21.43 2.5 7.41 9.45 9.45 0.149 9.45 13.85 4 4.61 5.88 5.88 0.143 5.88 8.30 6 3.08 3.93 3.93 0.134 3.93 5.58 10 1.83 2.333 2.333 0.132 2.337 3.37 16 1.15 1.466 1.466 0.124 1.471 2.16 25 0.727 0.927 0.927 0.121 0.935 1.41 35 0.524 0.668 0.669 0.115 0.679 1.046 50 0.387 0.493 0.494 0.111 0.506 0.800 70 0.268 0.342 0.343 0.105 0.359 0.584 95 0.193 0.246 0.248 0.103 0.269 0.451 120 0.153 0.195 0.197 0.100 0.221 0.377 150 0.124 0.158 0.160 0.100 0.189 0.326 185 0.0991 0.126 0.129 0.099 0.163 0.282 240 0.0754 0.0961 0.0993 0.097 0.139 0.238 300 0.0601 0.0766 0.0812 0.096 0.126 0.212 400 0.0470 0.0599 0.0636 0.094 0.114 0.186 500 0.0366 0.0467 0.0513 0.092 0.105 0.167 630 0.0283 0.0361 0.042 0.091 0.100 0.153 LOW VOLTAGE MULTI CORE CABLE

LINEAR RESISTANCE, REACTANCE AND VOLTAGE DROP

XLPE INSULATED (90°C) COPPER CONDUCTOR

SIZE R (DC) R (DC) R (AC) X Z VD mm2 20 90 90 90 1.5 12.1 15.43 15.43 0.165 15.43 21.55 2.5 7.41 9.45 9.45 0.143 9.45 13.24 4 4.61 5.88 5.88 0.132 5.88 8.28 6 3.08 3.93 3.93 0.121 3.93 5.57 10 1.83 2.333 2.333 0.109 2.336 3.35 16 1.15 1.466 1.466 0.106 1.470 2.14 25 0.727 0.927 0.927 0.103 0.933 1.39 35 0.524 0.668 0.669 0.098 0.676 1.03 50 0.387 0.493 0.494 0.098 0.504 0.786 70 0.268 0.342 0.343 0.095 0.356 0.574 95 0.193 0.246 0.248 0.093 0.264 0.44 120 0.153 0.195 0.197 0.091 0.217 0.37 150 0.124 0.158 0.160 0.091 0.184 0.316 185 0.0991 0.126 0.129 0.091 0.1579 0.273 240 0.0754 0.0961 0.0993 0.090 0.1340 0.231 300 0.0601 0.0766 0.0812 0.090 0.1212 0.206 400 0.0470 0.0599 0.0636 0.089 0.1094 0.181 500 0.0366 0.0467 0.0513 0.088 0.1019 0.163 630 0.0283 0.0361 0.0420 0.088 0.0975 0.150 R(DC) :

20Direct Current Resistance at 20°C, Ohm/Km X : Reactance, Ohm / Km R(DC) :

90Direct Current Resistance at 90°C, Ohm/Km Z : Impedance, Ohm / Km R(AC) :

90Alternating Current Resistance at 90°C, Ohm/Km VD : Voltage Drop (Phase to Phase), V/A.Km XLPE INSULATED, PVC SHEATHED CABLES

ALUMINIUM CONDUCTORS

600/1000 VOLTS

LOW VOLTAGE SINGLE CORE CABLE (IN TREFOIL FORMATION)

LINEAR RESISTANCE, REACTANCE AND VOLTAGE DROP

XLPE INSULATED (90°C) ALUMINIUM CONDUCTOR

SIZE R (DC) R (DC) R (AC) X Z VD mm2 20 90 90 90 16 1.91 2.449 2.449 0.124 2.452 3.522 25 1.20 1.539 1.539 0.121 1.544 2.258 35 0.868 1.113 1.113 0.115 1.119 1.662 50 0.641 0.822 0.822 0.111 0.829 1.254 70 0.443 0.568 0.568 0.105 0.578 0.896 95 0.32 0.410 0.411 0.103 0.424 0.677 120 0.253 0.324 0.325 0.100 0.340 0.554 150 0.206 0.264 0.265 0.100 0.283 0.471 185 0.164 0.210 0.211 0.099 0.233 0.395 240 0.125 0.160 0.162 0.097 0.189 0.325 300 0.100 0.128 0.130 0.096 0.162 0.280 400 0.0778 0.100 0.102 0.094 0.139 0.239 500 0.0605 0.078 0.081 0.092 0.123 0.208 630 0.0469 0.06 0.064 0.091 0.111 0.183 LOW VOLTAGE MULTI CORE CABLE (IN TREFOIL FORMATION)

LINEAR RESISTANCE, REACTANCE AND VOLTAGE DROP

XLPE INSULATED (90°C) ALUMINIUM CONDUCTOR

SIZE R (DC) R (DC) R (AC) X Z VD mm2 20 90 90 90 16 1.91 2.449 2.449 0.106 2.451 3.504 25 1.20 1.539 1.539 0.103 1.542 2.240 35 0.868 1.113 1.113 0.098 1.117 1.644 50 0.641 0.822 0.822 0.098 0.828 1.241 70 0.443 0.568 0.568 0.095 0.576 0.886 95 0.320 0.410 0.411 0.093 0.421 0.666 120 0.253 0.324 0.325 0.091 0.337 0.545 150 0.206 0.264 0.265 0.091 0.280 0.462 185 0.164 0.210 0.211 0.091 0.230 0.387 240 0.125 0.160 0.162 0.090 0.185 0.318 300 0.100 0.128 0.130 0.090 0.158 0.274 400 0.0778 0.100 0.102 0.089 0.135 0.234 500 0.0605 0.078 0.081 0.088 0.120 0.204 630 0.0469 0.060 0.064 0.088 0.109 0.180 R(DC) :

20Direct Current Resistance at 20°C, Ohm/Km X : Reactance, Ohm / Km R(DC) :

90Direct Current Resistance at 90°C, Ohm/Km Z : Impedance, Ohm / Km R(AC) :

90Alternating Current Resistance at 90°C, Ohm/Km VD : Voltage Drop (Phase to Phase), V/A.Km

Cables and Conductors should be installed by trained personnel in accordance with good engineering practices, recognized codes of practice, statutory local requirements, IEE wiring regulations and where relevant, in accordance with any specific instructions issued by the company. Cables are often supplied in heavy cable reels and handling these reels can constitute a safety hazard. In particulat, dangers may arise during the removal of steel binding straps and during the removal of retaining battens and timbers which may expose projecting nails.