Wires

High voltage power cables (HV): Up to 380 kV, ideal for transmission systems.

At ARBIAN EXPERTS Cables, all XLPE insulations of our High and Extra High Voltage Cables are done pursuant to standards outlined by IEC 60840 and IEC 62067, as applicable. The conductors used are Stranded Class 2 (round for 800 mm² and below and segmental for 1000 mm² and above); conductors are of plain annealed copper or aluminum up to 2500 mm² in accordance with IEC 60228.

Standard outer sheathing of our High Voltage Cables is extruded HDPE type ST7; other PE sheathing compounds such as LLDPE, LMDPE, and MDPE are available on request.

HV & EXTRA HV Cables Types

ARABIAN EXPERTS Cables started production of Medium voltage cables in 1986 and High Voltage Cables in 1994 and has supplied huge quantities of Medium Voltage Cables while in the High Voltage cable the cumulative quantity is more than 1000 kms of 132 kV and more than 1000 kms of 69 kV cables.

High Voltage cables from 66 kV to 230 kV with different constructions and material manufactured by ARABIAN EXPERTS Cables Group has been successfully type tested. 16 type tests have been performed on 132 kV cables, 6 of these type tests are with accessories. 4 type tests have been performed on 110-115 kV cables, 6 type tests have been performed on 69 kV cables and 1 type test was performed on 230 kV Cable totaling 27 type tests which prove suitability of design stress up to 9 kV /mm and lower.

One of the above mentioned type test for 132 kV cable was performed at KEMA Netherlands and 2 type tests on 132 kV Cables have been performed at ARABIAN EXPERTS Cables Laboratories witnessed by KEMA, Netherlands which prove the reliability and dependability of ARABIAN EXPERTS Cables High Voltage Cables and its testing laboratories. Certification from KEMA for these tests are enclosed in this catalogue.

Long-term tests were also performed both at ARABIAN EXPERTS Cables Laboratories and King Saud University (6 months, 1 year, 2 years) to prove the high quality of RC manufactured cables. Breakdown tests with different constant voltages and time gave the result that cables designed at a stress of 13 kV/mm can survive more than 30 years which gives an indication that RC high voltage cables can be designed at a stress level of 8 kV/mm with a good safety margin other than the values which were considered during evaluation.

As mentioned above, ARABIAN EXPERTS Cables has manufactured a 230 kV cable with a stress level of 8 kV/mm. This cable was type tested as per IEC 62067 and IEC 60840 and the type test results are satisfactory. Long-term testing for 230 kV complete cable system shall be performed with this cable.

ARABIAN EXPERTS Cables have qualified engineers and the required software to design high voltage circuits based on local conditions. Current rating, Induced voltage, Short circuit current for conductor and screen are computed to meet customer requirement, positive, negative and zero sequence impedance are computed for Engineering purpose and Network protection.

Experienced engineers provide supervision and certified professional jointers perform the required cable laying and accessory installations. To cope with International awareness, ARABIAN EXPERTSCables have purchased a HVAC site test system, which provides more accurate results about the installation and workmanship quality without affecting the system at any point. Also, very soon partial discharge test measurement equipment at site for terminations using Professor Lemke technique shall be made available which can provide a very clear indication about the termination condition and deficiency (if any) caused during installation.

Special Features of High Voltage Cables Manufactured by Riyadh Cables Group:

I. MATERIAL:

- Super smooth inner semi-conducting layer where electrical stress is at its maximum value. This shall improve the cable electrical characteristics, cable breaking strength and extend the lifetime of cable.

- Super-clean XLPE insulation material as contamination is one ofthe main cause of water-tree initiation in the insulation material. The level of cleanliness is higher than the requirements specified in AEIC CS7.

- For Watertight constructions, water swellable powder shall be provided in the conductor interstices to prevent ingress of water along the conductor axis in case of cable failure due to any reason.

- For watertight constructions, water swellable tapes under and over metallic screen shall be used to prevent ingress of water longitudinally, in case of damage to the outer sheath. Also, water swellable tapes shall keep the cable interior enough dry so that triggering of water trees shall be considerably minimized.

- For Radial Watertight constructions, copolymer coated Laminated Aluminium tape of 0.2 mm thickness is provided to prevent radial water penetration since polymeric material might allow water to diffuse in very small quantities with the passage oftime and this shall affect the cable performance in the long run.

The metal-copolymer laminate consists of an Aluminium tape with co-polymer lamination on both sides. During extrusion of PE sheath the extruded sheath will fuse with the bonded PE lamination of metal-polyethylene laminate to form one unit. This ensures 100% radial watertight construction and shall effectively seal the underneath layers of the cable perfectly preventing penetration of moisture into the cable. - Outer sheath of high-density polyethylene (HOPE), which can resist the force, applied on the cable while pulling and it is also the best polymeric material as radial water barrier.

II. PROCESSING:

1. Material Handling and Conveying System: Super clean material handling and conveying system enhances the keenness of RCGC in maintaining the material at the highest level of cleanliness for the manufactured cable.

2. Triple Extrusion: Riyadh Cables employs state-of-the-art triple cross-head extrusion where the conductor screen, insulation and insulation screen are extruded simultaneously by means of a triple cross-head which has the following advantages:

- Uniform insulation structure.

- Ensures extremely accurate layer thickness

- Ensures high purity in the frontier limit between the semi-conductive layers and insulation

- Provides optimal fusion of the individual layers without contamination.

- Ensures a firm bond and smooth interface between each layer thus improving electrical properties.

- Prevents unforeseen damage to the conductor or insulation screen during manufacturing process.

3. Dry Curing (Peroxide Curing): The Insulated conductor is fed into the cross¬linking zone where a computer caldulated and controlled heat treatment takes place in a dry inert gas (nitrogen) pressurized atmosphere (dry curing).

Cross-linking is done by agent di-cumyl peroxide (DCP). Cross-linking takes place in the CCV Tube under heated and pressurized Nitrogen where DCP decomposes into two radicals which react with Polyethylene thereby causing cross linking.

Peroxide is already mixed at the material supplier’s plant with the proper balance of Anti-oxidant and Peroxide to ensure the required thermal stability and optimum curing level. Therefore, no mixing whatsoever is done at Riyadh Cables, this will prevent any problems, which might occur due to the unbalanced mixing of the material in the production stage as some other manufacturers do. Un-packing and handling of the material is also done in similar super clean environment at RCGC details of which are given in this catalogue.

The mixing ratio is about 1 to 1.5 PHR with very small amount of anti-oxidant. The cross-link residual is gas, which defuses out of the insulation gradually. Other residuals are Acetophone and Cumyl-alcohol, which are in very low ratio. Research in this regard has proven that this material has very good effect on the insulation such as:

- It improves the breaking strength.

- It slows water tree growth in the XLPE material under service.

- Curing is done in heated and pressurized nltrogen which reduces micro voids and moisture content in the insulation and ensures enhanced and stable breakdown strength.

1. Dry Cooling: The hot cross-linked core passes into the cooling part of the line to be cooled in a dry inert gas (Nitrogen) pressurized atmosphere (dry cooling) which can reduce the moisture content to the lowest level.

2. Quality Control: Performing very strict quality control during processing such as using X-ray unit for thickness measurement in continuous mode for all extruded layers. This arrangement also facilitates recording of the trend every 2 seconds. The unit continuously scans 3600 geometry of the cable and displays maximum, minimum and eccentricity of all three layers separately. Any deviation between specified values and measured values are recorded and adjusted automatically.

Also included in the CCV line is the “Twin Rot System” one of the latest in manufacturing technology, which ensures superior control of eccentricity and eliminates the possibility of pear-drop as the cable rotates during manufacture.

Use of a very sophisticated software for temperature adjustment in the curing zone of CCV line ensures optimum XLPE characteristics are achieved.

nsulating Compounds for Cable

| Insulating Compound | Maximum conductor temperature °C | |

|---|---|---|

| Normail Operation | Short Circuit (Max. duration 5s) | |

| Low density thermoplastic polyethylene (PE) | 70 | 130 1) |

| High density thermoplastic polyethylene (HDPE) | 80 | 160 1) |

| Cross-linked polyethylene (XLPE) | 90 | 250 |

| Ethylene-propylene rubber (EPR) | 90 | 250 |

| High modulus or hard grade ethylene-propylene rubber (HEPR) | 90 | 250 |

| 1) For PE and HOPE, short circuit temperature up to 20° C in excess of those shown may be acceptable with suitable semi-conducting layers over the conductor and the insulation and by agreement between manufacturer and purchaser. | ||

Over Sheathing Compounds for Cables

| SB, XB | Both ends | SB, XB |

|---|---|---|

| Polyvinyl Chloride (PVC) | ST1 | 80 |

| ST2 | 90 | |

| Polyethylene | ST3 | 80 |

| ST4 | 90 |

Tan δ Requirements for Insulating Compounds for Cables

| Designation of Compound | PE | HDPE | EPR/HEPR | XLPE |

|---|---|---|---|---|

| Maximum tan 10-4 | 10 | 10 | 50 | 10 1) |

| 1) For cables produced with an XLPE compound containing special additives, the maximum tan δ is 50×10 -4 | ||||

Cable Losses :

Cable losses can be divided as current dependent a nd voltage dependent. Voltage dependent losses arise in the di-electric due to change of polarity in the alternating field which di-electric losses.

Di-electric loss per unit length in each phase is given by:

Wd=w C U2o tan (W/m)

Current dependent cable losses comprise of the following:

- Ohmic conductor losses

- Losses due to skin effect

- Losses due to proximity effect

- Losses in metallic sheath

Ohmic conductor losses: These are dependent on the material and temperature and are calculated as follows:

Wc = 12R (W/m)

where:

R is the a.c resistance of conductor at operating temperature and calculated as

R = R2 ( [1 a(t-20)]

a = 0.00393 for Copper,

a = 0.00403 for Aluminium,

t = temperature in °C

Losses due to skin effect: These are caused by the displacement of the current into the outer areas of the conductor and increase approximately with the square of the frequency. These can be reduced by special conductor constructions (segmental conductors). The losses can make up to 8 to 17% of the ohmic losses of the conductor for cross-sections between 500 mm2 to 2000 mm2.

Losses due to proximity effect: These are caused by parallel conductors laid close together Le., by magenetic fields. If the cables are laid far apart, the effect can be reduced to 10% of the ohmic conductor losses even for large conductor cross-sections.

Sheath Losses: Power loss in sheath or screen are caused by eddy currents and induced sheath current

Eddy current losses are produced in all metal parts adjacent to the conductor especially in presence of large conductor currents.

Induced sheath current: Because the metal sheath of a single core cable is linked much more closely to the alternating magenetic field of its own conductor than to the altrernating current field of the other two phase conductors, the result is an induced voltage along the length of the cable. This amounts to approximately 60 to 150 V/km per kA of the conductor current for practical installation purpose. If the sheath is bonded at both ends, this results in a longitudinal sheath current with correspnding extra losses in the sheath.

If longitudinal sheath resistance Rm is known, the following formula can be used to determine sheath current Im:

- X

M

- = ω x 0.2 x Ln

- x 10

-3

- Ui = X

M

- I L

- Z

M

- = (R

M

- ² + X

M

- ²)

½

- I

M

- =

- Where :

- X

M

- = Mutual reactance of sheath (Ω/Km)

- S = Space between cable axis (mm).

- d

M

- = Mean diameter of sheath (mm).

- Ui = Induced voltage on sheath (kV)

- Z

M

- = Sheath Impedance (Ω/Km)

- I = Phase current (kA)

- Sheath losses are calculated as follows:

- Ws = I

M

- ² x R

M

Bonding Systems: In addition, extra losses can arise as a result of magnetic reversal on ferrous materials in the vicinity us the cable. Sheath losses may influence the ampacity of the cables considerably. These can be reduced by grounding the sheath at one end only, in which case the free cable end has to be fitted with over voltage protection. The disadvantage of the one side grounding is that the zero sequence impedance rises considerably, possibly leading to interferance problems with nearby tele-communication cables. Another method fo reducing sheath losses is cross-bonding.

Single point Bonding: In case the actual circuit is too small to accommodate one or two lengths, single point bonding can be adopted where the sheath is directly bonded at one end and is bqnded through an SVL at the other end. In this case there shall be no circulating currents but, there shall be induced voltage at one end, the value of which can be computed. Induced voltage here can be treated in a similar way as for cross-bonding system. In case of fault, the maximum acceptable induced voltage depends on outer sheath characteristics and in such case a ground continuity conductor is required to carry the earth fault and also help in reducing the induced voltage during earth fault conditions.

Cross bonding system: This can be considered when the circuit length can be sub-divided into major sections and each major section can be divided into three equal minor sections taking into consideration the reduction in number of joints to a minimum as the weakest point in the circuit is the joint.

It is possible to reduce the resultant sheath voltage to low levels. Particularly with larger conductor cross-sections and on cable lengths with joints, by carrying cross bonding at about every 1/3rd of the sheath length of each phase in series, reduces the resultant sheath voltage to zero. Even sheath grounded at both ends, reduces the extra sheath losses drastically. The zero sequence impednace is practically of the same low level as in normal both end grounded system.

The cyclic permutation of longitudinal sheath connections results in similar sheath over voltage problems at points where the subdivided sheaths are insulated as in single grounded cable sheath. Therefore, these insulated points will have to be provided with suitable over voltage protection (surge arrestors, non-linear silicon-carbide or zinc oxide resistors)

Mixed System: Sometimes mixed system Le., cross-bonding and single point bonding in the same circuit can be used where the number of minor sections cannot be divided over 3 such as 4 or 5 sections. Here cross-bonding system can be considered for the first 3 sections and single point bonding used for the other section(s).

CU/XLPE/CUW/LAT/PE – 69 KV (72.5 KV)

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 199 | 20.4 | 13.0 | 49.6 | 0.2 | 4.00 | 66 | 7700 |

| 400 | 199 | 23.2 | 13.0 | 52.4 | 0.2 | 4.00 | 69 | 8600 |

| 500 | 199 | 26.7 | 13.0 | 55.9 | 0.2 | 4.00 | 73 | 9800 |

| 630 | 199 | 30.4 | 13.0 | 59.6 | 0.2 | 4.00 | 76 | 11300 |

| 800 | 199 | 33.7 | 13.0 | 62.9 | 0.2 | 4.00 | 80 | 13100 |

| 1000 * | 199 | 41.0 | 13.0 | 70.2 | 0.2 | 4.00 | 87 | 15800 |

| 1200 * | 199 | 44.0 | 13.0 | 73.2 | 0.2 | 4.00 | 90 | 17600 |

| 1600 * | 199 | 50.0 | 13.0 | 79.2 | 0.2 | 4.00 | 96 | 21300 |

| 2000 * | 199 | 56.0 | 13.0 | 85.2 | 0.2 | 4.00 | 102 | 25500 |

* Round Segmental Conductor

** 199 mm² CUW screen shall withstand 31.5 kA for 1 second [non-adiabatic]

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0788 | 0.42 | 0.83 | 0.17 | 42.93 | 31.5 | 348 | 394 | 455 | 558 | 607 | 692 |

| 400 | 0.0470 | 0.0627 | 0.41 | 0.80 | 0.19 | 57.23 | 31.5 | 383 | 445 | 516 | 629 | 699 | 802 |

| 500 | 0.0366 | 0.0503 | 0.39 | 0.78 | 0.20 | 71.54 | 31.5 | 417 | 502 | 585 | 707 | 805 | 933 |

| 630 | 0.0283 | 0.0408 | 0.37 | 0.75 | 0.22 | 90.14 | 31.5 | 452 | 561 | 660 | 787 | 921 | 1080 |

| 800 | 0.0221 | 0.0340 | 0.36 | 0.73 | 0.24 | 114.47 | 31.5 | 481 | 619 | 735 | 860 | 1033 | 1229 |

| 1000 | 0.0176 | 0.0240 | 0.34 | 0.69 | 0.28 | 143.08 | 31.5 | 537 | 742 | 870 | 1008 | 1285 | 1518 |

| 1200 | 0.0151 | 0.0211 | 0.33 | 0.68 | 0.29 | 171.70 | 31.5 | 558 | 793 | 936 | 1066 | 1394 | 1661 |

| 1600 | 0.0113 | 0.0169 | 0.32 | 0.65 | 0.32 | 228.93 | 31.5 | 594 | 889 | 1068 | 1172 | 1605 | 1954 |

| 2000 | 0.0090 | 0.0144 | 0.31 | 0.63 | 0.35 | 286.17 | 31.5 | 619 | 961 | 1176 | 1256 | 1780 | 2213 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

** Flat formation with both ends bonded system is not recommended

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

CU/XLPE/CUW/LEAD/PE – 69 KV (72.5 KV)

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 156 | 20.4 | 13.0 | 49.6 | 2.5 | 4.00 | 71 | 12800 |

| 400 | 152 | 23.2 | 13.0 | 52.4 | 2.5 | 4.00 | 74 | 13900 |

| 500 | 149 | 26.7 | 13.0 | 55.9 | 2.5 | 4.00 | 78 | 15400 |

| 630 | 147 | 30.4 | 13.0 | 59.6 | 2.5 | 4.00 | 81 | 17300 |

| 800 | 145 | 33.7 | 13.0 | 62.9 | 2.5 | 4.00 | 85 | 19300 |

| 1000 | 140 | 41.0 | 13.0 | 70.2 | 2.5 | 4.00 | 92 | 22700 |

| 1200 | 138 | 44.0 | 13.0 | 73.2 | 2.5 | 4.00 | 95 | 24700 |

| 1600 | 134 | 50.0 | 13.0 | 79.2 | 2.5 | 4.00 | 101 | 28900 |

| 2000 | 129 | 56.0 | 13.0 | 85.2 | 2.5 | 4.00 | 107 | 33600 |

* Round Segmental Conductor

** Specified size of CUW screen along with the LEAD sheat shall withstand 31.5 kA for 1sec [non-adiabatic], [for special constructions, screen area may vary slightly]

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0787 | 0.44 | 0.83 | 0.17 | 42.93 | 31.5 | 351 | 397 | 457 | 569 | 618 | 703 |

| 400 | 0.0470 | 0.0626 | 0.42 | 0.80 | 0.19 | 57.23 | 31.5 | 386 | 448 | 518 | 642 | 711 | 814 |

| 500 | 0.0366 | 0.0502 | 0.40 | 0.78 | 0.20 | 71.54 | 31.5 | 421 | 504 | 587 | 722 | 818 | 946 |

| 630 | 0.0283 | 0.0406 | 0.38 | 0.75 | 0.22 | 90.14 | 31.5 | 456 | 564 | 662 | 805 | 935 | 1095 |

| 800 | 0.0221 | 0.0337 | 0.37 | 0.73 | 0.24 | 114.47 | 31.5 | 487 | 621 | 737 | 880 | 1049 | 1246 |

| 1000 | 0.0176 | 0.0240 | 0.35 | 0.69 | 0.28 | 143.08 | 31.5 | 545 | 739 | 872 | 1033 | 1297 | 1537 |

| 1200 | 0.0151 | 0.0210 | 0.34 | 0.68 | 0.29 | 171.70 | 31.5 | 566 | 788 | 938 | 1093 | 1404 | 1680 |

| 1600 | 0.0113 | 0.0168 | 0.33 | 0.65 | 0.32 | 228.93 | 31.5 | 605 | 880 | 1068 | 1206 | 1612 | 1975 |

| 2000 | 0.0090 | 0.0143 | 0.32 | 0.63 | 0.35 | 286.17 | 31.5 | 633 | 949 | 1174 | 1296 | 1782 | 2234 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949 for both CUW & LEAD sheath

** Flat formation with both ends bonded system is not recommended

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 216 | 20.4 | 16.5 | 55 | 0.2 | 3.95 | 73 | 8500 |

| 400 | 216 | 23.2 | 16.5 | 57.8 | 0.2 | 3.95 | 76 | 9400 |

| 500 | 216 | 26.7 | 16.5 | 61.3 | 0.2 | 3.95 | 79 | 10700 |

| 630 | 216 | 30.4 | 16.5 | 65.2 | 0.2 | 3.95 | 83 | 12200 |

| 800 | 216 | 33.7 | 16.5 | 68.5 | 0.2 | 3.95 | 87 | 14100 |

| 1000 * | 216 | 41.0 | 16.5 | 76.1 | 0.2 | 3.95 | 94 | 16900 |

| 1200 * | 216 | 44.0 | 16.5 | 79.1 | 0.2 | 3.95 | 97 | 18700 |

| 1600 * | 216 | 50.0 | 16.5 | 85.1 | 0.2 | 3.95 | 103 | 22400 |

| 2000 * | 216 | 56.0 | 16.5 | 91.1 | 0.2 | 3.95 | 109 | 26700 |

* Round Segmental Conductor

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 400 | 0.0470 | 0.0626 | 0.42 | 0.80 | 0.15 | 57.23 | 34.42 | 385 | 447 | 514 | 631 | 695 | 788 |

| 500 | 0.0366 | 0.0501 | 0.41 | 0.78 | 0.17 | 71.54 | 34.42 | 420 | 504 | 582 | 710 | 800 | 915 |

| 630 | 0.0283 | 0.0405 | 0.39 | 0.75 | 0.18 | 90.14 | 34.42 | 455 | 565 | 657 | 792 | 916 | 1059 |

| 800 | 0.0221 | 0.0336 | 0.38 | 0.73 | 0.19 | 114.47 | 34.42 | 485 | 623 | 732 | 866 | 1029 | 1205 |

| 1000 | 0.0176 | 0.0239 | 0.35 | 0.69 | 0.22 | 143.08 | 34.42 | 540 | 745 | 867 | 1016 | 1278 | 1489 |

| 1200 | 0.0151 | 0.0210 | 0.35 | 0.68 | 0.24 | 171.70 | 34.42 | 561 | 796 | 933 | 1075 | 1385 | 1628 |

| 1600 | 0.0113 | 0.0167 | 0.33 | 0.65 | 0.26 | 228.93 | 34.42 | 596 | 893 | 1064 | 1182 | 1596 | 1913 |

| 2000 | 0.0090 | 0.0143 | 0.32 | 0.63 | 0.28 | 286.17 | 34.42 | 622 | 967 | 1170 | 1268 | 1771 | 2165 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 400 | 216 | 24.0 | 16.5 | 58.6 | 0.2 | 3.95 | 77 | 7100 |

| 500 | 216 | 27.0 | 16.5 | 61.6 | 0.2 | 3.95 | 80 | 7700 |

| 630 | 216 | 30.4 | 16.5 | 65.2 | 0.2 | 3.95 | 83 | 8300 |

| 800 | 216 | 35.0 | 16.5 | 69.8 | 0.2 | 3.95 | 88 | 9200 |

| 1000 | 216 | 42.0 | 16.5 | 77.1 | 0.2 | 3.95 | 95 | 10500 |

| 1200 | 216 | 44.0 | 16.5 | 79.1 | 0.2 | 3.95 | 97 | 11200 |

| 1600 | 216 | 50.0 | 16.5 | 85.1 | 0.2 | 3.95 | 103 | 12600 |

| 2000 | 216 | 56.0 | 16.5 | 91.1 | 0.2 | 3.95 | 109 | 14300 |

* Round Segmental Conductor

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 400 | 0.0778 | 0.1014 | 0.42 | 0.80 | 0.15 | 37.79 | 34.42 | 321 | 353 | 403 | 519 | 551 | 622 |

| 500 | 0.0605 | 0.0798 | 0.40 | 0.77 | 0.17 | 47.24 | 34.42 | 356 | 401 | 459 | 590 | 638 | 723 |

| 630 | 0.0469 | 0.0631 | 0.39 | 0.75 | 0.18 | 59.52 | 34.42 | 393 | 455 | 522 | 669 | 737 | 842 |

| 800 | 0.0367 | 0.0509 | 0.37 | 0.72 | 0.20 | 75.59 | 34.42 | 428 | 511 | 590 | 752 | 848 | 979 |

| 1000 | 0.0291 | 0.0383 | 0.35 | 0.69 | 0.23 | 94.48 | 34.42 | 477 | 596 | 683 | 877 | 1024 | 1179 |

| 1200 | 0.0247 | 0.0328 | 0.35 | 0.68 | 0.24 | 113.38 | 34.42 | 501 | 645 | 741 | 936 | 1117 | 1293 |

| 1600 | 0.0186 | 0.0254 | 0.33 | 0.65 | 0.26 | 151.17 | 34.42 | 543 | 736 | 854 | 1051 | 1308 | 1534 |

| 2000 | 0.0149 | 0.0211 | 0.32 | 0.63 | 0.28 | 188.97 | 34.42 | 575 | 810 | 950 | 1146 | 1476 | 1754 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 275 | 20.4 | 16.5 | 55 | 0.2 | 3.95 | 74 | 9000 |

| 400 | 275 | 23.2 | 16.5 | 57.8 | 0.2 | 3.95 | 77 | 10000 |

| 500 | 275 | 26.7 | 16.5 | 61.3 | 0.2 | 3.95 | 80 | 11200 |

| 630 | 275 | 30.4 | 16.5 | 65.2 | 0.2 | 3.95 | 84 | 12800 |

| 800 | 275 | 33.7 | 16.5 | 68.5 | 0.2 | 3.95 | 87 | 14700 |

| 1000 | 275 | 41.0 | 16.5 | 76.1 | 0.2 | 3.95 | 95 | 17400 |

| 1200 | 275 | 44.0 | 16.5 | 79.1 | 0.2 | 3.95 | 98 | 19200 |

| 1600 | 275 | 50.0 | 16.5 | 85.1 | 0.2 | 3.95 | 104 | 23000 |

| 2000 | 275 | 56.0 | 16.5 | 91.1 | 0.2 | 3.95 | 110 | 27300 |

* Round Segmental Conductor

** 275 mm² CUW screen shall withstand 40 kA for 1 sec as per SEC-EOA specifications [adiabatic]

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0786 | 0.44 | 0.83 | 0.14 | 42.93 | 43.18 | 348 | 396 | 453 | 558 | 605 | 681 |

| 400 | 0.0470 | 0.0626 | 0.43 | 0.80 | 0.15 | 57.23 | 43.18 | 382 | 448 | 514 | 629 | 697 | 789 |

| 500 | 0.0366 | 0.0501 | 0.41 | 0.78 | 0.17 | 71.54 | 43.18 | 416 | 504 | 582 | 707 | 802 | 917 |

| 630 | 0.0283 | 0.0405 | 0.39 | 0.75 | 0.18 | 90.14 | 43.18 | 450 | 565 | 657 | 787 | 919 | 1061 |

| 800 | 0.0221 | 0.0336 | 0.38 | 0.73 | 0.19 | 114.47 | 43.18 | 479 | 624 | 732 | 860 | 1032 | 1207 |

| 1000 | 0.0176 | 0.0239 | 0.36 | 0.69 | 0.22 | 143.08 | 43.18 | 533 | 745 | 867 | 1007 | 1280 | 1492 |

| 1200 | 0.0151 | 0.0210 | 0.35 | 0.68 | 0.24 | 171.70 | 43.18 | 553 | 797 | 933 | 1064 | 1388 | 1631 |

| 1600 | 0.0113 | 0.0167 | 0.33 | 0.65 | 0.26 | 228.93 | 43.18 | 587 | 894 | 1064 | 1169 | 1600 | 1917 |

| 2000 | 0.0090 | 0.0143 | 0.32 | 0.63 | 0.28 | 286.17 | 43.18 | 611 | 968 | 1171 | 1252 | 1775 | 2169 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

AL/XLPE/CUW/LAT/PE – 69 KV (72.5 KV)

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 500 | 275 | 27.0 | 16.5 | 61.6 | 0.2 | 3.95 | 81 | 8200 |

| 630 | 275 | 30.4 | 16.5 | 65.2 | 0.2 | 3.95 | 84 | 8900 |

| 800 | 275 | 35.0 | 16.5 | 69.8 | 0.2 | 3.95 | 89 | 9800 |

| 1000 | 275 | 42.0 | 16.5 | 77.1 | 0.2 | 3.95 | 96 | 11100 |

| 1200 | 275 | 44.0 | 16.5 | 79.1 | 0.2 | 3.95 | 98 | 11700 |

| 1600 | 275 | 50.0 | 16.5 | 85.1 | 0.2 | 3.95 | 104 | 13200 |

| 2000 | 275 | 56.0 | 16.5 | 91.1 | 0.2 | 3.95 | 110 | 14800 |

* Round Segmental Conductor

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 500 | 0.0605 | 0.0798 | 0.41 | 0.77 | 0.17 | 47.24 | 43.18 | 354 | 402 | 459 | 589 | 639 | 725 |

| 630 | 0.0469 | 0.0631 | 0.39 | 0.75 | 0.18 | 59.52 | 43.18 | 390 | 455 | 523 | 666 | 739 | 844 |

| 800 | 0.0367 | 0.0509 | 0.37 | 0.72 | 0.20 | 75.59 | 43.18 | 424 | 512 | 591 | 749 | 850 | 981 |

| 1000 | 0.0291 | 0.0383 | 0.35 | 0.69 | 0.23 | 94.48 | 43.18 | 472 | 597 | 683 | 871 | 1026 | 1181 |

| 1200 | 0.0247 | 0.0328 | 0.35 | 0.68 | 0.24 | 113.38 | 43.18 | 495 | 645 | 742 | 929 | 1120 | 1295 |

| 1600 | 0.0186 | 0.0254 | 0.33 | 0.65 | 0.26 | 151.17 | 43.18 | 536 | 736 | 854 | 1042 | 1311 | 1536 |

| 2000 | 0.0149 | 0.0210 | 0.32 | 0.63 | 0.28 | 188.97 | 43.18 | 566 | 811 | 950 | 1135 | 1479 | 1757 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

** Flat formation with both ends bonded system is not recommended

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

/XLPE/CUW/LAT/PE – 132 KV (145 KV)

255mm² copper wire screen

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 255 | 20.4 | 18.0 | 59.6 | 0.2 | 4.50 | 77 | 9400 |

| 400 | 255 | 23.2 | 18.0 | 62.4 | 0.2 | 4.50 | 80 | 10300 |

| 500 | 255 | 26.7 | 18.0 | 65.9 | 0.2 | 4.50 | 84 | 11600 |

| 630 | 255 | 30.4 | 18.0 | 69.6 | 0.2 | 4.50 | 87 | 13200 |

| 800 | 255 | 33.7 | 18.0 | 72.9 | 0.2 | 4.50 | 91 | 15000 |

| 1000 * | 255 | 41.0 | 18.0 | 80.2 | 0.2 | 4.50 | 98 | 17900 |

| 1200 * | 255 | 44.0 | 18.0 | 83.2 | 0.2 | 4.50 | 101 | 19700 |

| 1600 * | 255 | 50.0 | 18.0 | 89.2 | 0.2 | 4.50 | 107 | 23400 |

| 2000 * | 255 | 56.0 | 18.0 | 95.2 | 0.2 | 4.50 | 113 | 27800 |

* Round Segmental Conductor

** 255 mm² CUW screen shall withstand 40 kA for 1 second.

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0786 | 0.45 | 0.83 | 9.14 | 42.93 | 40 | 349 | 397 | 452 | 558 | 604 | 677 |

| 400 | 0.0470 | 0.0625 | 0.44 | 0.80 | 0.15 | 57.23 | 40 | 383 | 449 | 513 | 629 | 696 | 783 |

| 500 | 0.0366 | 0.0500 | 0.42 | 0.78 | 0.16 | 71.54 | 40 | 418 | 506 | 581 | 707 | 801 | 909 |

| 630 | 0.0283 | 0.0404 | 0.40 | 0.75 | 0.18 | 90.14 | 40 | 452 | 567 | 656 | 788 | 916 | 1052 |

| 800 | 0.0221 | 0.0335 | 0.39 | 0.73 | 0.19 | 114.47 | 40 | 481 | 626 | 731 | 861 | 1029 | 1195 |

| 1000 | 0.0176 | 0.0239 | 0.36 | 0.69 | 0.21 | 143.08 | 40 | 534 | 746 | 865 | 1005 | 1272 | 1473 |

| 1200 | 0.0151 | 0.0210 | 0.35 | 0.68 | 0.23 | 171.70 | 40 | 554 | 798 | 931 | 1063 | 1380 | 1610 |

| 1600 | 0.0113 | 0.0167 | 0.34 | 0.65 | 0.25 | 228.93 | 40 | 589 | 895 | 1061 | 1168 | 1590 | 1891 |

| 2000 | 0.0090 | 0.0142 | 0.33 | 0.63 | 0.27 | 286.17 | 40 | 613 | 970 | 1168 | 1252 | 1765 | 2139 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

** Flat formation with both ends bonded system is not recommended.

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

CU/XLPE/CUW/LAT/PE – 132 KV (145 KV)

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 280 | 20.4 | 19.0 | 61.6 | 0.2 | 5.00 | 81 | 10000 |

| 400 | 280 | 23.2 | 19.0 | 64.4 | 0.2 | 5.00 | 84 | 11000 |

| 500 | 280 | 26.7 | 19.0 | 67.9 | 0.2 | 5.00 | 88 | 12200 |

| 630 | 280 | 30.4 | 19.0 | 71.6 | 0.2 | 5.00 | 91 | 13800 |

| 800 | 280 | 33.7 | 19.0 | 74.9 | 0.2 | 5.00 | 95 | 15700 |

| 1000 * | 280 | 41.0 | 19.0 | 82.2 | 0.2 | 5.00 | 102 | 18600 |

| 1200 * | 280 | 44.0 | 19.0 | 85.2 | 0.2 | 5.00 | 105 | 20400 |

| 1600 * | 280 | 50.0 | 19.0 | 91.2 | 0.2 | 5.00 | 111 | 24200 |

| 2000 * | 280 | 56.0 | 19.0 | 97.2 | 0.2 | 5.00 | 117 | 28600 |

* Round Segmental Conductor

** 280 mm² CUW screen as per SEC-COA requirement.

*** Specified nominal thickness of insulation as per SEC-COA Spec 5/16.

**** Specified nominal thickness of outer sheath as per SEC-COA requirement.

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0786 | 0.46 | 0.83 | 0.13 | 42.93 | 43.95 | 349 | 398 | 452 | 559 | 605 | 674 |

| 400 | 0.0470 | 0.0624 | 0.44 | 0.80 | 0.14 | 57.23 | 43.95 | 383 | 450 | 512 | 630 | 696 | 780 |

| 500 | 0.0366 | 0.0499 | 0.42 | 0.78 | 0.16 | 71.54 | 43.95 | 417 | 507 | 580 | 707 | 801 | 905 |

| 630 | 0.0283 | 0.0403 | 0.41 | 0.75 | 0.17 | 90.14 | 43.95 | 451 | 569 | 655 | 788 | 917 | 1047 |

| 800 | 0.0221 | 0.0334 | 0.39 | 0.73 | 0.18 | 114.47 | 43.95 | 480 | 628 | 730 | 861 | 1031 | 1189 |

| 1000 | 0.0176 | 0.0239 | 0.37 | 0.69 | 0.21 | 143.08 | 43.95 | 532 | 748 | 864 | 1003 | 1272 | 1465 |

| 1200 | 0.0151 | 0.0209 | 0.36 | 0.68 | 0.22 | 171.70 | 43.95 | 552 | 800 | 930 | 1060 | 1379 | 1600 |

| 1600 | 0.0113 | 0.0166 | 0.35 | 0.65 | 0.24 | 228.93 | 43.95 | 586 | 898 | 1060 | 1165 | 1590 | 1879 |

| 2000 | 0.0090 | 0.0141 | 0.33 | 0.63 | 0.26 | 286.17 | 43.95 | 610 | 973 | 1166 | 1248 | 1765 | 2124 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

** Flat formation with both ends bonded system is not recommended.

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

U/XLPE/CUW/LEAD/PE – 132 KV (145 KV)

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 206 | 20.4 | 18.0 | 59.6 | 2.5 | 4.50 | 83 | 15400 |

| 400 | 202 | 23.2 | 18.0 | 62.4 | 2.5 | 4.50 | 86 | 16600 |

| 500 | 202 | 26.7 | 18.0 | 65.9 | 2.5 | 4.50 | 90 | 18200 |

| 630 | 199 | 30.4 | 18.0 | 69.6 | 2.5 | 4.50 | 93 | 20000 |

| 800 | 195 | 33.7 | 18.0 | 72.9 | 2.5 | 4.50 | 97 | 22200 |

| 1000 * | 192 | 41.0 | 18.0 | 80.2 | 2.5 | 4.50 | 104 | 25700 |

| 1200 * | 188 | 44.0 | 18.0 | 83.2 | 2.5 | 4.50 | 107 | 27700 |

| 1600 * | 185 | 50.0 | 18.0 | 89.2 | 2.5 | 4.50 | 113 | 32000 |

| 2000 * | 181 | 56.0 | 18.0 | 95.2 | 2.5 | 4.50 | 119 | 36800 |

* Round Segmental Conductor

** Specified size of CUW screen along with the LEAD sheath shall withstand 40 kA for 1 sec [non-adiabatic], [for special constructions, screen area may vary slightly]

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0785 | 0.47 | 0.83 | 0.14 | 42.93 | 40 | 351 | 399 | 454 | 568 | 614 | 686 |

| 400 | 0.0470 | 0.0624 | 0.45 | 0.80 | 0.15 | 57.23 | 40 | 385 | 451 | 515 | 640 | 706 | 794 |

| 500 | 0.0366 | 0.0499 | 0.43 | 0.78 | 0.16 | 71.54 | 40 | 420 | 508 | 583 | 719 | 812 | 921 |

| 630 | 0.0283 | 0.0402 | 0.41 | 0.75 | 0.18 | 90.14 | 40 | 454 | 568 | 658 | 801 | 929 | 1065 |

| 800 | 0.0221 | 0.0333 | 0.40 | 0.73 | 0.19 | 114.47 | 40 | 484 | 627 | 733 | 877 | 1042 | 1210 |

| 1000 | 0.0176 | 0.0238 | 0.37 | 0.69 | 0.21 | 143.08 | 40 | 537 | 742 | 866 | 1022 | 1282 | 1489 |

| 1200 | 0.0151 | 0.0209 | 0.37 | 0.68 | 0.23 | 171.70 | 40 | 558 | 792 | 931 | 1082 | 1388 | 1627 |

| 1600 | 0.0113 | 0.0166 | 0.35 | 0.65 | 0.25 | 228.93 | 40 | 593 | 885 | 1060 | 1190 | 1594 | 1909 |

| 2000 | 0.0090 | 0.0141 | 0.34 | 0.63 | 0.27 | 286.17 | 40 | 619 | 954 | 1164 | 1277 | 1764 | 2156 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949 for both CUW & LEAD sheath

** Flat formation with both ends bonded system is not recommended

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

| PROPERTIES | Low Density PE | MDPE | HDPE | Irradiated PE (XLPE) | XLPEa |

|---|---|---|---|---|---|

| Volume resistivity, Ω – cm | > 1016 | > 1016 | > 1015 | > 1015 | > 1015 |

| Dielectric strength Short time, v/mil | 460-700 | 500-700 | 450-500 | 2500b | 550 |

| Step-by-step, V/mil | 420-700 | 500-700 | 440-600 | 1800b | 500 |

| Dielectric Constant | |||||

| 60 Hz | 2.3 | 2.3 | 2.35 | 2.3 | 2.30 |

| 103 Hz | 2.3 | 2.3 | 2.35 | 2.3 | – |

| 106 Hz | 2.3 | 2.3 | 2.35 | 2.3 | 2.28 |

| Dissipation factor | |||||

| 60 Hz | 0.0002 | 0.0002 | 0.0002 | 0.0005 | 0.0003 |

| 103 Hz | 0.0002 | 0.0002 | 0.0002 | 0.0005 | |

| 106 Hz | 0.0002 | 0.0002 | 0.0002 | 0.0005 | 0.0004 |

| Arc resistance, s (ASTM D495) | Melts | Melts | > 125 | – | – |

| Density, g/cm3 | 0.910-0.925 | 0.926-0.940 | 0.941-0.965 | 0.92 | 0.92 |

| Modulos of elasticity in tension, psi x 105 | 0.17-0.35 | 0.25-0.55 | 0.8-1.5 | – | – |

| Percent elongation, % (ult.) | 20-650 | 100-600 | 15-700 | > 200 | 550 |

| Tensile strength | 14-19 | 19-26 | 26-45 | – | 24 |

| Compressive strength, psi x 103 | – | – | 2.4 | – | – |

| Rockwell hardness | R10 | R15 | R30-R50 | – | (Shore D) |

| Impact strength, ft-lb/in. | – | – | 1-23 | – | 45 |

| Heat distortion temperature (at 66 psi), °F | 105-121 | 120-150 | 140-185 | – | – |

| Thermal conductivity, cal/cm.s. °C x 10-4 | 8 | – | 11-12 | – | – |

| Thermal expansion, in/in. per °C x 10-5 | 11-30 | 15-30 | 15-30 | 20 | – |

| Water absorption, % | < 0.02 | < 0.02 | < 0.01 | Nil | – |

| Burning Gate | Slow | Slow | Slow | – | – |

| aUnion Carbide HFDE-4201 NR EC crosslinkable compound. bA 5-mil film. | |||||

PHYSICAL PROPERTIES OF PVC, THERMOPLASCTIC INSULATION

AND SEMI-CONDUCTIVE POLYETHYLENE JACKETS

| Physical Property | Test Method | PVC | LDPE | LLDPE | LPDPE | LHDPE | Semiconducting Thermoplastic PE |

|---|---|---|---|---|---|---|---|

| Melt index (190°, 2.1 kg), g/10 min | ASTM D1238 | – | 0.25 | 0.55 | 0.70 | 0.15 | |

| Density (23°C) g/cm3 | ASTM D1505 | – | 0.93 | 0.93 | 0.95 | 0.96 | 1.12 |

| Tensile strength Psi | ASTM | > 1500 | 2100 | 2350 | 3500 | 4000 | 1600 |

| Mpa | D638 | 10.3 | 14.5 | 15.5 | 24.1 | 27.6 | 11.0 |

| Tensile elongation percent | ASTM D638 | > 100 | 650 | 650 | 900 | 800 | 250 |

| DSC melting point °C Flexural modulus | – | 110 | 119 | 125 | 130 | ||

| Psi | ASTM | – | 38,000 | 55,000 | 90,000 | 145,000 | |

| Mpa | D790 | 262 | 379 | 621 | 1000 | ||

| Dielectric Constant (1 MHz) | ASTM D1531 | – | 2.60 | 2.50 | 2.52 | 2.56 | |

| Dissipation factor (1 MHz) rad | ASTM D1531 | – | 0.005 | 0.0003 | 0.0003 | 0.0003 | |

| Dielectric strength, 0.030 in. Insulation thickness at 500V/s rate of rise V/mil kV/mm | ASTM D149 | – | – | 1230 46.6 | |||

| Heat distortion at 115°C | – | 90 | 22 | 7 | 0 | ||

| 121°C | 20 | ||||||

| 135°C | – | Melted | Melted | Melted | Melted | ||

| Abrasion resistance, mg/100 revolutions | ASTM D3389 | – | 29 | 22 | 16 | 14 | |

| Shore D hardness | ASTM D2240 | – | 54 | 56 | 61 | 66 | |

| Cut-througth resistance lb | – | 2600 | 3000 | 3600 | 4000 | ||

| N x 104 | – | 1.20 | 1.3 | 1.6 | 1.8 | ||

| Water vapor transmission G/24 hr/m2 | ASTM E96 | 310.0 | 1.16 | 0.74 | 0.51 | 0.32 | < 1.5 |

| Brittleness temperature, °C | ASTM D3389 | – | – | -60 | – | – | -24 |

Note : LDPE, LLDPE, LMDPE, LHDPE, and semiconducting thermoplastic PE are Union carbide compounds.

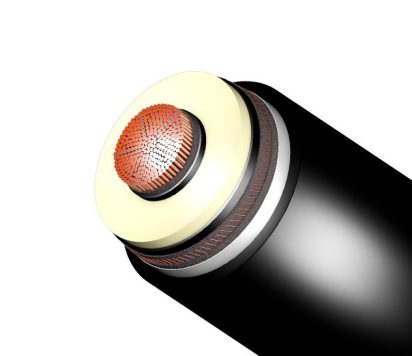

High Voltage Cables are usually single core. The Basic Design of High Voltage XLPE Cables is as shown below:

CU/XLPE/CUW/PE

CU/XLPE/CUT/PE

CU/XLPE/LEAD/PE

CU/XLPE/CUW/LAT/PE

CU/XLPE/CUW/LEAD/PE

Construction

Conductors: Conductors are made of Copper or Aluminium. Conductors upto and including cross¬sectional area 800 mm2 are of round stranded compacted type. Conductors of cross¬sectional area 1000 mm2 upto 2000 mm2 are of Milliken design i.e., 5 segments and one central round conductor assembled together to form a overall round section. This is in order to reduce the skin effect and ensure better compaction and flexibility. Conductors shall comply in design and properties with IEC 60228.

Conductor formation comprises mainly of drawing and stranding. Wires of required diameter are drawn in drawing machines and stranding performed in stranding machines. In-process Quality Control monitor the specified requirements to ensure that the conductor meets the requirements.

Extrusion

Semi-conductive screens and Insulation: The Inner semi-conductive layer (conductor screen), XLPE insulation and the outer semi¬conductive layer (insulation screen) are applied simultaneously over the compacted conductor by triple extrusion.

Extrusion of the above is performed in continuous caternary vulcanizing (CCV) line specially designed for manufacture of high voltage cables. Each component of the line has been carefully selected to ensure the best quality product.

Material and Material Handling

Specifically chosen, approved standard quality super clean material from the world renowned leading manufacturers of XLPE material is used alongwith super smooth material for semi-conductive screens as the compounds should meet strict standards of cleanliness.

Utmost precaution is taken to ensure cleanliness during handling and conveying of the material. A clean room material handling and conveying system designed by German Companies specialized in clean room technology is installed which ensures a cleanliness better than class 100 of US Federal standard 209D.

Quality Control and Testing

High voltage cables are subjected to continuous monitoring and tests are performed starting from the time of receiving material right through various stages of production and routine testing.

Routine Tests, Sample tests and Type tests (when required) are carried out in accordance with IEC, AEIC and other related International Standards. Table showing the test requirements as per IEC 60840 are shown in Table.

Riyadh Cables has equipped itself with the most modern laboratories and equipment including the following test fields:

1) Routine test field with a large shielded enclosure for carrying out routine high voltage tests, high voltage tests, partial discharge measurements up to 400 kVat a noise level below 2 pC and for measurements oftangent delta.

2) Extra high voltage laboratory containing basically a 2400 kV impulse generator, 400 kV AC test system extendable upto 800 kV and heating equipment for conducting special tests, type tests on high voltage cables and accessories, longterm tests and tests to determine breakdown data.

CU/XLPE/CUW/LAT/PE – 110 KV (123 KV)

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 95 | 20.4 | 18.0 | 60 | 0.2 | 4.50 | 76 | 7800 |

| 400 | 95 | 23.2 | 18.0 | 62.8 | 0.2 | 4.50 | 79 | 8800 |

| 500 | 95 | 26.7 | 18.0 | 66.3 | 0.2 | 4.50 | 83 | 10100 |

| 630 | 95 | 30.4 | 18.0 | 70 | 0.2 | 4.50 | 86 | 11700 |

| 800 | 95 | 33.7 | 18.0 | 73.3 | 0.2 | 4.50 | 90 | 13500 |

| 1000 * | 95 | 41.0 | 18.0 | 80.6 | 0.2 | 4.50 | 97 | 16300 |

| 1200 * | 95 | 44.0 | 18.0 | 83.6 | 0.2 | 4.50 | 100 | 18200 |

| 1600 * | 95 | 50.0 | 18.0 | 89.6 | 0.2 | 4.50 | 106 | 21900 |

| 2000 * | 95 | 56.0 | 18.0 | 95.6 | 0.2 | 4.50 | 112 | 26300 |

* Round Segmental Conductor

** 95 mm² CUW screen as per SEC-WOA specifications.

*** Minimum required thickness ofinsulation is 16.0 mm as per SEC-WOA specifications.

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0786 | 0.45 | 0.83 | 0.14 | 42.93 | 15.83 | 366 | 396 | 452 | 574 | 602 | 674 |

| 400 | 0.0470 | 0.0625 | 0.43 | 0.80 | 0.15 | 57.23 | 15.83 | 405 | 448 | 512 | 651 | 693 | 781 |

| 500 | 0.0366 | 0.0501 | 0.41 | 0.78 | 0.16 | 71.54 | 15.83 | 446 | 505 | 580 | 737 | 798 | 906 |

| 630 | 0.0283 | 0.0404 | 0.40 | 0.75 | 0.18 | 90.14 | 15.83 | 487 | 566 | 655 | 828 | 913 | 1048 |

| 800 | 0.0221 | 0.0335 | 0.38 | 0.73 | 0.19 | 114.47 | 15.83 | 524 | 624 | 730 | 912 | 1025 | 1191 |

| 1000 | 0.0176 | 0.0239 | 0.36 | 0.69 | 0.22 | 143.08 | 15.83 | 591 | 745 | 864 | 1081 | 1268 | 1468 |

| 1200 | 0.0151 | 0.0210 | 0.35 | 0.68 | 0.23 | 171.70 | 15.83 | 617 | 796 | 930 | 1150 | 1375 | 1605 |

| 1600 | 0.0113 | 0.0167 | 0.34 | 0.65 | 0.25 | 228.93 | 15.83 | 662 | 894 | 1061 | 1278 | 1584 | 1885 |

| 2000 | 0.0090 | 0.0142 | 0.33 | 0.63 | 0.27 | 286.17 | 15.83 | 694 | 968 | 1167 | 1379 | 1758 | 2132 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

** Flat formation with both ends bonded system is not recommended.

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

CU/XLPE/LEAD/PE – 115 KV (123 KV)

Dimensional Data

| Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|

| [mm²] | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 20.4 | 20.3 | 63.5 | 6.9 | 3.95 | 91 | 26600 |

| 400 | 23.2 | 20.3 | 66.3 | 6.6 | 3.95 | 93 | 27300 |

| 500 | 26.7 | 20.3 | 69.8 | 6.4 | 3.95 | 96 | 28800 |

| 630 | 30.4 | 20.3 | 73.7 | 6.1 | 3.95 | 100 | 30200 |

| 800 | 33.7 | 20.3 | 77 | 5.9 | 3.95 | 103 | 32100 |

| 1000 * | 41.0 | 20.3 | 84.3 | 5.4 | 3.95 | 109 | 34800 |

| 1200 * | 44.0 | 20.3 | 87.3 | 5.3 | 3.95 | 112 | 36800 |

| 1600 * | 50.0 | 20.3 | 93.3 | 5 | 3.95 | 117 | 40500 |

| 2000 * | 56.0 | 20.3 | 99.3 | 4.7 | 3.95 | 123 | 44700 |

* Round Segmental Conductor

** Specified nominal thickness of insulation as per AEIC CS7 as required by SEC-EOA.

*** Specified thickness of lead sheath is based on 40 kA for 1 sec [non-adiabatic], [for special constructions, lead sheath thickness may vary slightly]

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0785 | 0.49 | 0.83 | 0.13 | 42.93 | 40 | 369 | 397 | 454 | 589 | 614 | 686 |

| 400 | 0.0470 | 0.0623 | 0.47 | 0.80 | 0.13 | 57.23 | 40 | 409 | 446 | 514 | 668 | 703 | 793 |

| 500 | 0.0366 | 0.0498 | 0.44 | 0.78 | 0.15 | 71.54 | 40 | 449 | 500 | 581 | 756 | 806 | 919 |

| 630 | 0.0283 | 0.0401 | 0.43 | 0.75 | 0.16 | 90.14 | 40 | 490 | 557 | 655 | 849 | 919 | 1061 |

| 800 | 0.0221 | 0.0331 | 0.41 | 0.73 | 0.17 | 114.47 | 40 | 527 | 611 | 729 | 936 | 1027 | 1203 |

| 1000 | 0.0176 | 0.0238 | 0.38 | 0.69 | 0.19 | 143.08 | 40 | 595 | 715 | 859 | 1107 | 1250 | 1476 |

| 1200 | 0.0151 | 0.0209 | 0.37 | 0.68 | 0.20 | 171.70 | 40 | 621 | 758 | 922 | 1178 | 1348 | 1611 |

| 1600 | 0.0113 | 0.0165 | 0.36 | 0.65 | 0.22 | 228.93 | 40 | 668 | 840 | 1047 | 1312 | 1539 | 1884 |

| 2000 | 0.0090 | 0.0140 | 0.34 | 0.63 | 0.24 | 286.17 | 40 | 704 | 902 | 1146 | 1421 | 1695 | 2123 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949 for LEAD sheath

** Flat formation with both ends bonded system is not recommended

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

CU/XLPE/CUW/LAT/PE – 132 KV (145 KV)

95mm² copper wire screen

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 300 | 95 | 20.4 | 18.0 | 59.6 | 0.2 | 4.50 | 76 | 7800 |

| 400 | 95 | 23.2 | 18.0 | 62.4 | 0.2 | 4.50 | 79 | 8800 |

| 500 | 95 | 26.7 | 18.0 | 65.9 | 0.2 | 4.50 | 82 | 10100 |

| 630 | 95 | 30.4 | 18.0 | 69.6 | 0.2 | 4.50 | 86 | 11700 |

| 800 | 95 | 33.7 | 18.0 | 72.9 | 0.2 | 4.50 | 89 | 13500 |

| 1000 * | 95 | 41.0 | 18.0 | 80.2 | 0.2 | 4.50 | 96 | 16300 |

| 1200 * | 95 | 44.0 | 18.0 | 83.2 | 0.2 | 4.50 | 99 | 18200 |

| 1600 * | 95 | 50.0 | 18.0 | 89.2 | 0.2 | 4.50 | 105 | 21900 |

| 2000 * | 95 | 56.0 | 18.0 | 95.2 | 0.2 | 4.50 | 111 | 26300 |

* Round Segmental Conductor

** Screen cross-sectional area may vary according to the required short circuit current.

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 300 | 0.0601 | 0.0786 | 0.45 | 0.83 | 0.14 | 42.93 | 15.83 | 366 | 396 | 452 | 573 | 602 | 674 |

| 400 | 0.0470 | 0.0625 | 0.43 | 0.80 | 0.15 | 57.23 | 15.83 | 405 | 447 | 512 | 651 | 692 | 781 |

| 500 | 0.0366 | 0.0501 | 0.41 | 0.78 | 0.16 | 71.54 | 15.83 | 446 | 504 | 580 | 737 | 797 | 906 |

| 630 | 0.0283 | 0.0404 | 0.40 | 0.75 | 0.18 | 90.14 | 15.83 | 487 | 565 | 655 | 827 | 912 | 1048 |

| 800 | 0.0221 | 0.0335 | 0.38 | 0.73 | 0.19 | 114.47 | 15.83 | 523 | 624 | 730 | 911 | 1024 | 1191 |

| 1000 | 0.0176 | 0.0239 | 0.36 | 0.69 | 0.21 | 143.08 | 15.83 | 591 | 745 | 864 | 1081 | 1267 | 1468 |

| 1200 | 0.0151 | 0.0210 | 0.35 | 0.68 | 0.23 | 171.70 | 15.83 | 617 | 796 | 930 | 1149 | 1374 | 1605 |

| 1600 | 0.0113 | 0.0167 | 0.34 | 0.65 | 0.25 | 228.93 | 15.83 | 661 | 894 | 1061 | 1277 | 1584 | 1885 |

| 2000 | 0.0090 | 0.0142 | 0.33 | 0.63 | 0.27 | 286.17 | 15.83 | 693 | 968 | 1167 | 1377 | 1758 | 2133 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

** Flat formation with both ends bonded system is not recommended.

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

CU/XLPE/CUW/LEAD/PE – 132 KV (145 KV)

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 500 | 430 | 26.7 | 18.0 | 65 | 2.5 | 4.50 | 90 | 20400 |

| 630 | 430 | 30.4 | 18.0 | 68.7 | 2.5 | 4.50 | 94 | 22300 |

| 800 | 430 | 33.7 | 18.0 | 72 | 2.5 | 4.50 | 97 | 24500 |

| 1000 * | 430 | 41.0 | 18.0 | 79.6 | 2.5 | 4.50 | 105 | 28000 |

| 1200 * | 430 | 44.0 | 18.0 | 82.6 | 2.5 | 4.50 | 108 | 30100 |

| 1600 * | 430 | 50.0 | 18.0 | 88.6 | 2.5 | 4.50 | 114 | 34400 |

| 2000 * | 430 | 56.0 | 18.0 | 94.6 | 2.5 | 4.50 | 120 | 39200 |

* Round Segmental Conductor

** Specified screen cross-sectional area of 430 mm² shall withstand 40 kA for 3 sec as per SEC-SOA specs [non-adiabatic]

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 500 | 0.0366 | 0.0499 | 0.43 | 0.78 | 0.16 | 41.30 | 40 | 421 | 508 | 583 | 722 | 814 | 924 |

| 630 | 0.0283 | 0.0402 | 0.41 | 0.75 | 0.17 | 52.04 | 40 | 455 | 569 | 658 | 804 | 931 | 1068 |

| 800 | 0.0221 | 0.0333 | 0.40 | 0.73 | 0.18 | 66.09 | 40 | 484 | 627 | 733 | 879 | 1045 | 1213 |

| 1000 | 0.0176 | 0.0238 | 0.38 | 0.69 | 0.21 | 82.61 | 40 | 537 | 743 | 867 | 1026 | 1288 | 1497 |

| 1200 | 0.0151 | 0.0209 | 0.37 | 0.68 | 0.22 | 99.13 | 40 | 557 | 793 | 932 | 1084 | 1394 | 1635 |

| 1600 | 0.0113 | 0.0166 | 0.35 | 0.65 | 0.25 | 132.17 | 40 | 591 | 886 | 1061 | 1191 | 1601 | 1918 |

| 2000 | 0.0090 | 0.0141 | 0.34 | 0.63 | 0.27 | 165.22 | 40 | 616 | 955 | 1165 | 1276 | 1772 | 2166 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949 for CUW only.

** Flat formation with both ends bonded system is not recommended

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

CU/XLPE/CUW/LEAD/PE – 132 KV (145 KV)

Dimensional Data

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 500 | 364 | 26.7 | 20.3 | 69.8 | 2.5 | 4.50 | 96 | 20700 |

| 630 | 364 | 30.4 | 20.3 | 73.8 | 2.5 | 4.50 | 100 | 22700 |

| 800 | 359 | 33.7 | 20.3 | 77.1 | 2.5 | 4.50 | 103 | 24800 |

| 1000 * | 354 | 41.0 | 20.3 | 84.4 | 2.5 | 4.50 | 110 | 28400 |

| 1200 * | 354 | 44.0 | 20.3 | 87.4 | 2.5 | 4.50 | 113 | 30500 |

| 1600 * | 349 | 50.0 | 20.3 | 93.4 | 2.5 | 4.50 | 119 | 34700 |

| 2000 * | 344 | 56.0 | 20.3 | 99.4 | 2.5 | 4.50 | 125 | 39600 |

* Round Segmental Conductor.

** Specified size of CUW screen along with the LEAD sheath shall withstand 40 kA for 3 sec.

*** Specified nominal thickness of insulation as per AEIC CS7 as required by SEC-SOA.[for special constructions, screen area may vary slightly]

Electrical Data

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 500 | 0.0366 | 0.0498 | 0.44 | 0.78 | 0.15 | 41.30 | 40 | 421 | 509 | 581 | 720 | 809 | 910 |

| 630 | 0.0283 | 0.0401 | 0.43 | 0.75 | 0.16 | 52.04 | 40 | 455 | 571 | 656 | 804 | 926 | 1052 |

| 800 | 0.0221 | 0.0331 | 0.41 | 0.73 | 0.17 | 66.09 | 40 | 485 | 629 | 731 | 879 | 1039 | 1195 |

| 1000 | 0.0176 | 0.0238 | 0.39 | 0.69 | 0.19 | 82.61 | 40 | 536 | 744 | 863 | 1023 | 1275 | 1469 |

| 1200 | 0.0151 | 0.0208 | 0.38 | 0.68 | 0.20 | 99.13 | 40 | 555 | 793 | 928 | 1081 | 1380 | 1605 |

| 1600 | 0.0113 | 0.0165 | 0.36 | 0.65 | 0.22 | 132.17 | 40 | 589 | 886 | 1056 | 1188 | 1586 | 1881 |

| 2000 | 0.0090 | 0.0140 | 0.35 | 0.63 | 0.24 | 165.22 | 40 | 613 | 956 | 1159 | 1273 | 1756 | 2123 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949 for both CUW & LEAD sheath

** Flat formation with both ends bonded system is not recommended

Laying Conditions

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 630 | 255 | 30.4 | 22.0 | 77.6 | 0.2 | 4.50 | 95 | 14200 |

| 800 | 255 | 33.7 | 22.0 | 80.9 | 0.2 | 4.50 | 99 | 16200 |

| 1000 * | 255 | 41.0 | 22.0 | 88.2 | 0.2 | 4.50 | 106 | 19100 |

| 1200 * | 255 | 44.0 | 22.0 | 91.2 | 0.2 | 4.50 | 109 | 20900 |

| 1600 * | 255 | 50.0 | 22.0 | 97.2 | 0.2 | 4.50 | 115 | 24800 |

| 2000 * | 255 | 56.0 | 22.0 | 103.2 | 0.2 | 4.50 | 121 | 29200 |

* Round Segmental Conductor

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 630 | 0.0283 | 0.0402 | 0.42 | 0.75 | 0.15 | 90.14 | 40 | 443 | 552 | 637 | 787 | 903 | 1026 |

| 800 | 0.0221 | 0.0332 | 0.40 | 0.73 | 0.16 | 114.47 | 40 | 471 | 608 | 709 | 861 | 1014 | 1165 |

| 1000 | 0.0176 | 0.0238 | 0.38 | 0.69 | 0.18 | 143.08 | 40 | 521 | 721 | 836 | 1005 | 1249 | 1433 |

| 1200 | 0.0151 | 0.0209 | 0.37 | 0.68 | 0.19 | 171.70 | 40 | 540 | 770 | 898 | 1064 | 1354 | 1565 |

| 1600 | 0.0113 | 0.0165 | 0.35 | 0.65 | 0.21 | 228.93 | 40 | 572 | 862 | 1021 | 1171 | 1560 | 1836 |

| 2000 | 0.0090 | 0.0141 | 0.34 | 0.63 | 0.23 | 286.17 | 40 | 594 | 931 | 1120 | 1256 | 1732 | 2075 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949

** Flat formation with both ends bonded system is not recommended.

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

| Conductor Cross section | Conductor Cross section | Diameter of Conductor (approx) | Thickness of Insulation (nom) | Diameter over Insulation (approx) | Thickness of LAT (nom) | Thickness of Outer Sheath (nom) | Overall Diameter (approx) | Weight of Cable (approx) |

|---|---|---|---|---|---|---|---|---|

| [mm²] | [mm²]** | [mm] | [mm] | [mm] | [mm] | [mm] | [mm] | [kg/km] |

| 630 | 192 | 30.4 | 22.0 | 77.6 | 2.5 | 4.50 | 101 | 21700 |

| 800 | 192 | 33.7 | 22.0 | 80.9 | 2.5 | 4.50 | 105 | 23900 |

| 1000 | 185 | 41.0 | 22.0 | 88.2 | 2.5 | 4.50 | 112 | 27500 |

| 1200 | 185 | 44.0 | 22.0 | 91.2 | 2.5 | 4.50 | 115 | 29600 |

| 1600 | 181 | 50.0 | 22.0 | 97.2 | 2.5 | 4.50 | 121 | 33900 |

| 2000 | 169 | 56.0 | 22.0 | 103.2 | 2.5 | 4.50 | 126 | 38700 |

* Round Segmental Conductor

| Conductor Cross Section | Parameters | Short Circuit Current kA for 1 second | Continuous Current Rating [Amperes] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rdc at 20°C | Rdc at 90°C | Inductance (Nominal) mH/km | Capacitance (Nominal) | Single Circuit in Ground | In Free Air & Shaded Area | ||||||||

| Close Trefoil | Flat** | Close Trefoil | Flat** | ||||||||||

| [mm²] | Ω/km | Ω/km | Trefoil | Flat | µF/Km | Conductor | Screen* | Both Ends | Single/ cross | Single/ cross | Both Ends | Single/ cross | Single/ cross |

| 630 | 0.0283 | 0.0401 | 0.43 | 0.75 | 0.15 | 90.14 | 40 | 446 | 553 | 639 | 799 | 912 | 1037 |

| 800 | 0.0221 | 0.0331 | 0.41 | 0.73 | 0.16 | 114.47 | 40 | 475 | 609 | 710 | 875 | 1024 | 1177 |

| 1000 | 0.0176 | 0.0238 | 0.39 | 0.69 | 0.18 | 143.08 | 40 | 525 | 716 | 836 | 1022 | 1255 | 1446 |

| 1200 | 0.0151 | 0.0208 | 0.38 | 0.68 | 0.19 | 171.70 | 40 | 544 | 763 | 898 | 1082 | 1359 | 1579 |

| 1600 | 0.0113 | 0.0165 | 0.36 | 0.65 | 0.21 | 228.93 | 40 | 577 | 850 | 1019 | 1192 | 1561 | 1850 |

| 2000 | 0.0090 | 0.0140 | 0.35 | 0.63 | 0.23 | 286.17 | 40 | 602 | 914 | 1116 | 1281 | 1725 | 2085 |

* Maximum permissible non-adiabatic short circuit current as per IEC 949 for both CUW & LEAD sheath

| – Ground Temperature | 35 | °C |

|---|---|---|

| – Ground Thermal Resistivity | 2.0 | K.m/W |

| – Laying Depth | 1500 | mm |

| – Air Temperature | 50 | °C |

|---|---|---|

| – Number of Circuits | 1 | circuit |

| – Distance between Conductors (flat) | 400 | mm |

|

| ||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Variation in Phase Spacing of Cables*, Single Circuit in flat formation in ground | |||||

|---|---|---|---|---|---|

| Phase Spacing [mm] | 200 | 250 | 300 | 400 | 500 |

| Correction Factor | 0.92 | 0.95 | 0.97 | 1.00 | 1.02 |

| Groups of Circuits in Ground in Trefoil Formation | |||||||

|---|---|---|---|---|---|---|---|

| Distance “cc” between Groups [mm] | Number of Groups | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| 400 | 0.80 | 0.69 | 0.64 | 0.60 | 0.58 | 0.55 | 0.54 |

| 500 | 0.82 | 0.72 | 0.67 | 0.62 | 0.60 | 0.59 | 0.57 |

| 800 | 0.86 | 0.76 | 0.72 | 0.69 | 0.67 | 0.65 | 0.64 |

| 1000 | 0.87 | 0.79 | 0.75 | 0.72 | 0.70 | 0.69 | 0.68 |

| 1200 | 0.89 | 0.81 | 0.78 | 0.75 | 0.74 | 0.72 | 0.71 |

| 1500 | 0.90 | 0.84 | 0.81 | 0.79 | 0.78 | 0.77 | 0.76 |

| 2000 | 0.93 | 0.88 | 0.86 | 0.84 | 0.83 | 0.82 | 0.81 |

| Groups of Circuits in Ground in Flat Formation | |||||||

|---|---|---|---|---|---|---|---|

| Distance “cc” between Groups [mm] | Number of Groups | ||||||

| 2 | 3 | 4 | 5 | 6 | 7 | 8 | |

| 1250 | 0.87 | 0.78 | 0.75 | 0.72 | 0.71 | 0.69 | 0.68 |

| 1500 | 0.89 | 0.81 | 0.78 | 0.75 | 0.74 | 0.73 | 0.72 |

| 2000 | 0.91 | 0.85 | 0.83 | 0.81 | 0.8 | 0.79 | 0.78 |

| 3000 | 0.95 | 0.9 | 0.89 | 0.88 | 0.87 | 0.86 | 0.85 |

Note : The overall accuracy of correction factors is within ± 3%.